Lawrence Livermore National Laboratory (LLNL) researchers have used multimaterial, 3-D printing to create tailored gradient refractive index glass optics that could make for better military specialized eyewear and virtual reality goggles.

The new technique could achieve a variety of conventional and unconventional optical functions in a flat glass component (with no surface curvature), offering new optical design versatility in environmentally stable glass materials.

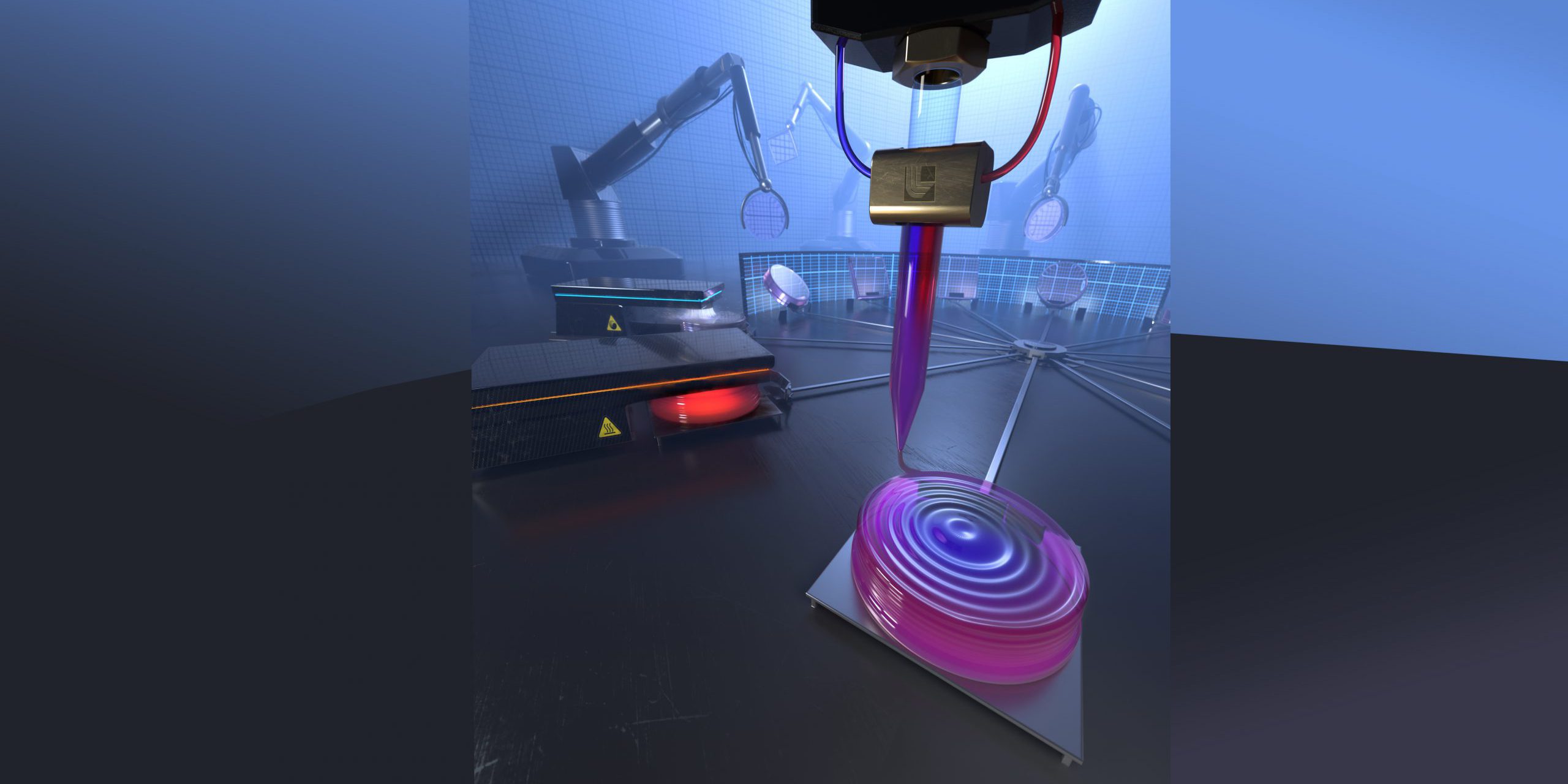

The team was able to tailor the gradient in the material compositions by actively controlling the ratio of two different glass-forming pastes or “inks” blended together inline using the direct ink writing (DIW) method of 3-D printing. After the composition-varying optical preform is built using DIW, it is then densified to glass and can be finished using conventional optical polishing.

“The change in material composition leads to a change in refractive index once we convert it to glass,” said LLNL scientist Rebecca Dylla-Spears, lead author of a paper appearing today in Science Advances.

The project started in 2016 when the team began looking at ways that additive manufacturing could be used to advance optics and optical systems. Because additive manufacturing offers the ability to control both structure and composition, it provided a new path to manufacturing of gradient refractive index glass lenses.