REDSTONE ARSENAL, Ala. – It’s a question Lance Hall asks of his U.S. Army Combat Capabilities Development Command Aviation & Missile Center customers, “What do you want your part to do?”

The answer he proposes is made possible by the AvMC Additive Manufacturing Facility.

When AvMC opened the doors to the facility in 2020, it was more than just a new physical space – it was a new way to serve the Warfighter. Additive manufacturing is a type of advanced manufacturing that can be used in all areas of a product life cycle from concept development to design, prototyping, production, and sustainment. Whether it’s a rotorcraft part that’s not scheduled for an industry production line for another two years or it’s printed conductive materials on the inside of a missile case, additive manufacturing and AvMC ensure the Army is ready to fight tonight.

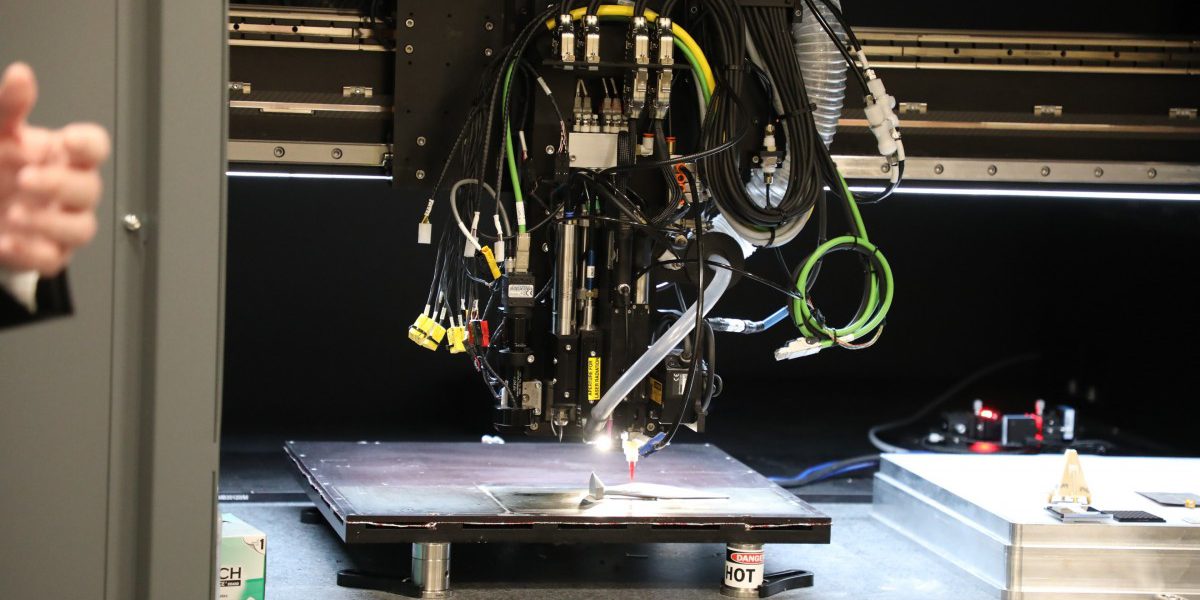

The center-wide asset not only enhances AvMC’s science and technology core competencies but also supports modernization priorities established by the Army Futures Command. The facility’s equipment includes the DMG Mori Lasertec 4300 3D, the 3DSystems ProX DMP 320, Stratasys Fortus 450MC, Object 350 Connex3, and the nScrypt 3Dn-1000. In-house capabilities now include material jetting, the ability to print conductive traces on the inside of tubular structures, laser powder bed technology, and blown-powder deposition inside of a traditional multiaxis turning/milling center.