In the quest for advanced vehicles with higher energy efficiency and ultralow emissions, Oak Ridge National Laboratory (ORNL) researchers are accelerating a research engine that gives scientists and engineers an unprecedented view inside the atomic-level workings of combustion engines in real time.

The new capability is an engine built specifically to run inside a neutron beamline. This neutronic engine provides a unique sample environment that allows investigation of structural changes in new alloys designed for the environment of a high-temperature, advanced combustion engine operating in realistic conditions.

ORNL first unveiled the capability in 2017, when researchers successfully evaluated a small, prototype engine with a cylinder head cast from a new high-temperature, aluminum-cerium alloy created at the lab. The experiment was the world’s first in which a running engine was analyzed by neutron diffraction, using the VULCAN neutron diffractometer at the Department of Energy’s Spallation Neutron Source, or SNS, at ORNL.

The results of the research, published in the Proceedings of the National Academy of Sciences, not only proved the hardiness of the unique alloy but also demonstrated the value of using nondestructive methods such as neutrons to analyze new materials.

Neutrons are deeply penetrating, even through dense metals. When neutrons scatter off atoms in a material, they provide researchers with a wealth of structural information down to the atomic scale. In this case, scientists determined how the alloys performed in operating conditions, such as high heat and extreme stress or tension, to identify even the smallest defects.

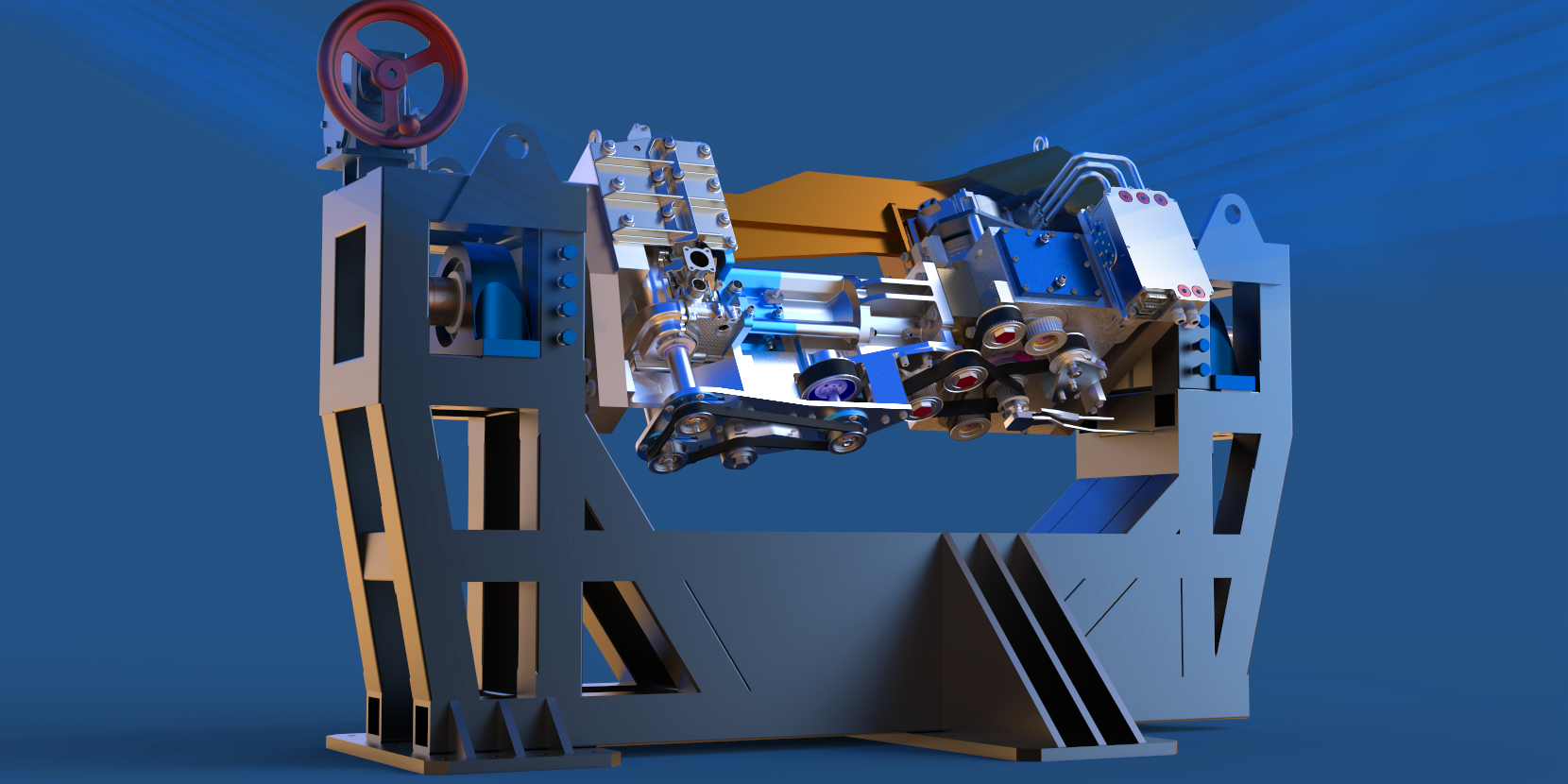

The experiment’s success has prompted ORNL to design a purpose-built research engine at industry-relevant scale for use in VULCAN. The capability is based on a two-liter, four-cylinder automotive engine, modified to operate on one cylinder to conserve sample space on the beamline. The engine platform can be rotated around the cylinder axis to give maximum measurement flexibility. The engine is custom-designed for neutron research, including the use of fluorocarbon-based coolant and oil, which improves visibility into the combustion chamber.