an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

Department of Defense (DoD) and Commercial Aircraft Transparency Construction, Materials, and Applications

Posted on February 3, 2018 | Completed on June 2, 2017 | By: Scott E. Armistead

What are the different materials, manufacturing methods, and properties for aircraft transparencies?

Defense Systems Information Analysis Center (DSIAC) staff responded to a technical inquiry on materials, manufacturing methods, and properties for transparent aircraft parts like windshields or windscreens, canopies, windows, and blast shields. DSIAC developed a report that identifies materials (layers and coatings) used in military aircraft transparencies; predominant material differences in transparencies for different classes of aircraft (fighter jets, bombers, cargo/transport aircraft, rotary wing aircraft, etc.); material use cases and benefits; production methods; and studies regarding differentiation of the materials among aircraft.

Specifically, the report includes information on the following:

- Various types of transparencies, diagrams for each, and a list of transparency manufacturers.

- Differences in and production of both monolithic (single-layer) and laminate (multi-layer) transparencies.

- Differences in materials used and their benefits.

- Differences in application of these materials to various types of aircraft.

- Differences in application of these materials to military and commercial aircraft, accompanied by the titles and references for over 20 data sheets for specific military and commercial aviation aircraft transparencies.

- Various types and the purpose of materials used in main structural layers and interlayers of transparencies.

- Additional exterior and interior layers and other special coatings applied to transparencies for environmental protection, crew spall shielding, electromagnetic protection, and other purposes.

Additionally, DSIAC researched U.S. Department of Defense attack, fighter, and bomber transparency information from available Defense Technical Information Center reports and developed a table. The table documents transparency type, manufacturer, structure, number and order of plies and interlayers, and material type and thickness for each ply or interlayer.

1.0 Introduction

The Defense Systems Information Analysis Center (DSIAC) staff searched the Defense Technical Information Center (DTIC) database and open sources for materials used in military aircraft transparencies for different classes of aircraft (fighter jets, bombers, cargo/transport aircraft, rotary wing aircraft, etc.). DSIAC also searched for studies on the differentiation of materials used in aircraft transparencies.

DSIAC compiled the results of the effort and generated descriptions detailing various types of transparencies; differences in production methodologies; differences in materials used and their purpose; application to various aircraft types; and aircraft transparency manufacturers. DSIAC also provided the inquirer with the titles and references for over 20 data sheets for specific military and commercial aviation aircraft transparencies. Additionally, DSIAC staff researched DTIC reports to generate a table that documents transparency type, manufacturer, structure, number/order of plies and interlayers, and material type/thickness for each ply or interlayer of a specific aircraft.

The author of this response, Scott Armistead, also provided valuable information related to the TI request. He is currently the Senior Staff Engineer for DSIAC and has over 30 years of experience as a systems engineer. He has supported U.S. government, military, and defense industry research, development, testing, and evaluation related to weapon systems (from medium-caliber ammunition to missiles and precision-guided munitions); weapons effectiveness; and military and commercial ground vehicle and aircraft survivability (susceptibility and vulnerability) against both kinetic- and directed-energy threats.

2.0 Aircraft Transparencies

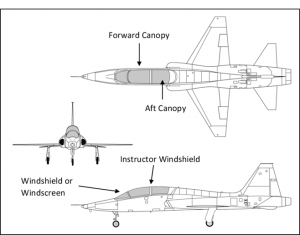

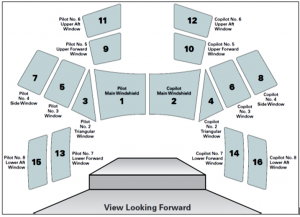

Aircraft transparencies are characterized by location. A windshield or windscreen is a transparency in the forward section of the cockpit, and it provides the primary area of vision for the pilots. Windshields are usually a single piece or a left/right pair. A canopy mainly provides vision to the side and overhead areas and may be configured as a single canopy (F-16), two canopies in tandem (T-38), or two canopy hatches side-by-side (F-111). A window is generally a relatively smaller transparency designed to provide additional side vision and may be almost anywhere on the aircraft. Additional types of transparencies include skylights, small overhead windows above the pilot(s), and eyebrows, which may be just aft of the windshield and provide additional vision for the forward overhead areas [1]. Figure 1 shows the relatively simple canopy and windshield arrangement for the T-38A. Figure 2 shows the more complicated arrangement of transparencies for the C-27J cockpit.

Figure 1: T-38A Transparencies [2].

Figure 2: C-27J Cockpit Transparencies [3].

2.1 Fixed-Wing Jet Aircraft Transparencies

Department of Defense (DoD) jet aircraft transparencies normally have a monolithic (single layer) or laminate (multilayer) composition. This composition consists of two to four core layers or “plies” that can be made from combinations of the following [1]:

- Polycarbonate (superior impact resistance and a high strength-to-weight ratio).

- Poly(methyl methacrylate) (PMMA) acrylic-type plastics, which are strong, lightweight, and have better abrasion resistance than polycarbonate.

- Advanced composite plastics, which can provide the desired qualities of both acrylic and polycarbonate for enhanced performance.

- Glass, which can be specifically formulated and/or chemically treated to provide improved impact and temperature shock resistance. Glass also stands up well to abrasion.

Depending on the fabrication method and materials, the core plies may be used as a structural material to help reduce overall airframe weight. Smaller, faster attack and fighter jet aircraft core plies tend to be made from plastics, whereas the larger, slower cargo jets may often incorporate glass [1].

Some common trade names for PMMA include Plexiglas®, Acrylite®, Lucite®, and Perspex®. Common trade names for polycarbonate include Lexan® and Makrolon®.

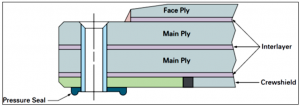

DoD aircraft transparencies may also have additional exterior and interior protective layers made of similar materials. The exterior ply is generally designed to provide additional protection from the environment, rain ablation resistance, etc. and may have other special coatings applied to it. The inner layer usually serves as a crew spall shield and is somewhat flexible to allow for thermal expansion while maintaining the bond between the plies [1].

2.1.1 Canopies

Canopies are generally made of monolithic or laminated acrylics and polycarbonates, whereas windshields and windows will many times incorporate glass layers or even be made of all glass layers (mission dependent). The complex curvature of canopies can make them difficult to fabricate and a variety of techniques including drape-molding, vacuum forming, etc. are used to control the shape during fabrication [1].

One of the more complex processes is that for the F-35 canopy fabricated by GKN Aerospace Transparency Systems. The acrylic and other special materials-based shell is loaded into a forming tool in an oven heated to 200⁰F where the canopy forms over a span of approximately 3 days. During that time, a control system automatically adjusts clamps to control the forming process and ensure the shape remains uniform [4].

The interlayer materials include polyurethane, silicone, and other proprietary materials with tailored optical properties that are used to bond the core plies together [1]. The interlayer materials can provide additional safety features such as bird-impact resistance, pressure “failsafe” capability, and anti-ice/anti-fog systems [5]. Commercial aircraft may include other technology such as electrically dimmable window technology [1]. A list of various transparency materials for DoD jet attack, fighter, bomber, and trainer aircraft is provided in Appendix A.

The F-16 has a plastic-laminated, polycarbonate-acrylic canopy as depicted in Figure 3. It consists of two to four acrylic and/or polycarbonate core plies, and one to three interlayers of polyurethane or silicone (manufacturer dependent). The innermost layer is drape-molded into the compound curvature shape, which is bonded to the outer layers by the polyurethane or silicone interlayers [6].

Figure 3: F-16 Canopy [7].

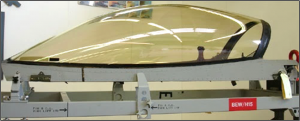

The F-22 canopy, depicted in Figure 4, is the largest piece of monolithic polycarbonate material being formed today. It has no canopy bow (frame), which is conducive to superior optics throughout the canopy (not just in the front) and offers the requisite low-observable features. The canopy is 3/4-in. thick and is actually made of two 3/8-in.-thick sheets that are heated, fusion bonded (the sheets meld to become a single piece), and then drape forged [8].

Figure 4: F-22 Canopy [9].

2.1.2 Coatings

Interior and/or exterior coatings may be applied to help protect transparencies and aircrews from various operational or environment threats, and they provide improved low-observable performance, solar-heat reduction, laser protection, and/or electromagnetic shielding. Such technologies are designed to be compatible with night vision systems and other optical requirements.

On some aircraft, the protective coating may have an obvious tint. A similar tinting may perform several different functions depending on the aircraft on which it is applied. For example, the gold coating on EA-6B canopies, depicted in Figure 5, protects the crew from the radiation emitted by their own jamming pods. Similar coatings on aircraft like the F-16 and F-22 may be used to prevent radiation from threat radar systems being reflecting off the interior cockpit structure to help reduce the aircraft radar cross-section.

Figure 5: EA-6B Canopy [10].

2.1.3 Transparency Construction

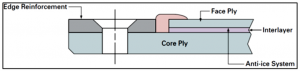

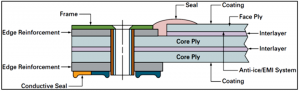

In general, each transparency will differ in its material and construction based on aircraft type and primary mission (e.g., Does the aircraft require a 350-knot standard or 550-knot impact-resistant canopy? Will the aircraft primarily be conducting day- or night-time missions? Are special electro-optical or electromagnetic coatings required?). Military aircraft may have relatively thicker face plies on the outer surface of the windshields, as well as a “crew shield” on the inboard side. Each manufacturer will have proprietary manufacturing processes and compositions for many of the structural, interlayer, and coating materials.

The transparencies are normally inserted or affixed to a metal frame for assembly. Some military aircraft with ejection systems may use explosive cord on the outer layer to fracture the material shortly before an ejection seat fires.

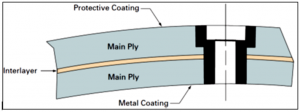

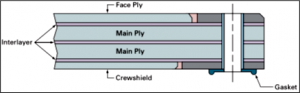

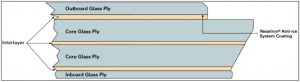

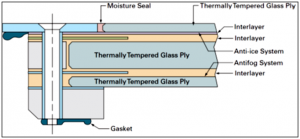

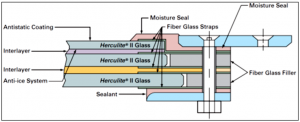

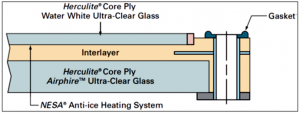

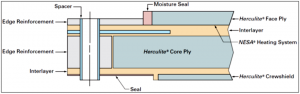

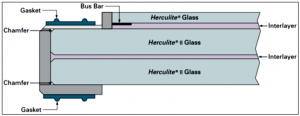

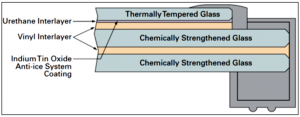

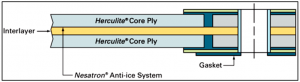

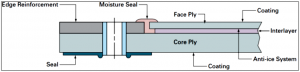

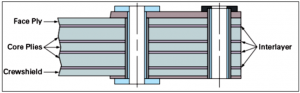

Figures 6–9 illustrate examples of construction layups for various U.S. military jet aircraft canopies and windscreens.

Figure 6: F-16 B/D Forward 550-knot Canopy [11].

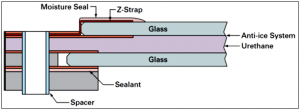

Figure 7: F-15 Windshield (Glass, Acrylic, and Polycarbonate Plies; Urethane Interlayers) [12]

Figure 8: F/A-18 Hornet and Super Hornet (Composite Plastics, Acrylic, and Polycarbonate Structural Layers; Urethane Interlayers) [13].

Figure 9: A-10 Center Windshield (Glass Plies, Urethane Interlayers) [14].

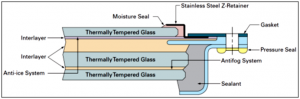

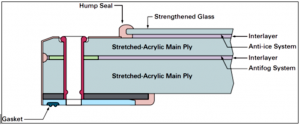

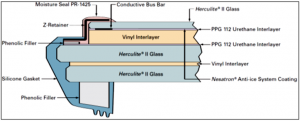

Commercial aviation and regional jet aircraft normally use a multilayer approach similar to military aircraft but tend to use more structural materials consisting of thermally tempered glass (e.g., Boeing 717 main windshields), combinations of lightweight, glass-faced acrylics or all-glass side cockpit windows (e.g., Boeing 747 series), or even multiple layers of stretched acrylic (e.g., next-generation 737). The material for the interlayer(s) for these configurations is normally urethane. The Airbus aircraft may also use a vinyl interlayer in addition to the urethane interlayer(s) (e.g., Airbus A300). Regional jet aircraft by Alena, Bombardier, Embraer, Merlin, SAAB, etc. are similar in construction. More prevalent in commercial aircraft where weight (which is closely associated with fuel economy) may be of higher concern, is the use of windshield and window structural plies that may be part of the airframe structural support to help reduce airframe weight. Damage to these windshields and windows could weaken the aircraft structural integrity. Figures 10–14 illustrate examples of commercial aviation jet aircraft windshield layups.

Figure 10: DC-10/MD-11 Main Windshield (Thermally Tempered Glass Plies, Urethane Interlayers) [15].

Figure 11: B-717, DC-9, MD-80, and MD-90 Cockpit Windows (Thermally Tempered Glass Plies, Urethane Interlayers) [16].

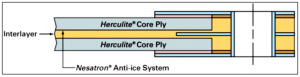

Figure 12: B-787 Main Windshield (Glass and Acrylic Plies, Urethane Interlayers) [17].

Figure 13: A300, A310, A330, and A340 Main Windshield (Glass Plies, Urethane, and Vinyl Interlayers) [18].

Figure 14: Embraer EMB 120, ERJ 135, ERJ 140, and ERJ 145XR Main Windshield (Glass Plies, Urethane, and Vinyl Interlayers) [19].

2.2 Fixed-Wing, Propeller-Driven Aircraft Transparencies

Although military and commercial/regional aviation propeller/turboprop aircraft normal cruising airspeeds are slower than their jet/turbofan counterparts (generally in the 200–350 knot range), their maximum operational airspeeds can be in the 400-knot plus region (e.g., 422 knot for the Airbus A400M and nearly 470 knots for the Tupulop Tu-114). Their transparencies tend to be similar to the slower varieties of large jet cargo craft and include more glass in their construction. Military variant examples of these aircraft include the A400M, An-32, C-130, CJ-27, Dash 8, E-2C, P-3, and Tu-95. Figures 15–19 illustrate examples of military and commercial aviation turboprop aircraft windshield layups.

Figure 15: C-130 Windshield, Forward Aft Side Windows, and Aft Side Windows (Glass Plies, Unknown Interlayer Material) [20].

Figure 16: P-3 Main Windshields and Center Windshield (Glass Plies, Unknown Interlayer Material) [21].

Figure 17: C-27J Windshield (Glass Plies, Unknown Interlayer Material) [3].

Figure 18: Bombardier Dash 8/Q Series Main Windshield (Glass Plies, Urethane and Vinyl Interlayers) [22].

Figure 19: Piaggio P.180 (Glass Plies, Urethane Interlayer) [23].

2.3 Rotary-Wing Aircraft Transparencies

One of the main differences between fixed-wing aircraft and rotary-wing aircraft, which generally have reduced transparency aero loading due to their slower airspeeds, is the use of thinner, single-ply overhead canopies and side windows made of stretched acrylic. These single layer structures usually start with flat PMMA sheets that are drape-molded over a mandrel. One of the closely guarded secrets of the original equipment manufacturers for the process is the grease they put on the mandrel so that the acrylic flows easily into shape.

Main windshields generally have a multilayered construction like that of the fixed-wing aircraft, though they may use fewer layers. The plies usually consist of a proprietary composition that includes structural glass materials with enhanced optical properties and impact and thermal shock-resistant properties. However, some (especially in general aviation) may use only acrylic and/or polycarbonate plies [24].

As with the fixed wing aircraft, advanced coatings may be used to protect transparencies and aircrews from various operational or environmental threats and/or provide low-observables performance, solar heat reduction, laser protection, and electromagnetic shielding. Electrical heating systems may also be incorporated to provide anti-ice/anti-fog protection. All technologies used in military rotary-wing aircraft are designed to be compatible with night vision systems [24]. Figures 20–24 illustrate examples of rotary-wing canopy and windshield layups.

Figure 20: CH-47 Windshields and Central Panel (Glass Plies, Unknown Interlayer Material) [25].

Figure 21: CH-53 Windshields and Central Panel (Advanced Composite Laminates, Unknown Interlayer Material) [26].

Figure 22: AH-64 Pilot Main Windshield (Glass Plies, Unknown Interlayer Material) [27].

Figure 23: V-22 Main Windshield (Acrylic and Polycarbonate Plies, Unknown Interlayer Materials) [28].

Figure 24: General Aviation Sikorsky S-92 Windshield (Acrylic and Polycarbonate Plies, Unknown Interlayer Material) [29].

In addition to canopies, windshields, and windows, rotary-wing aircraft may incorporate transparent “blast barriers.” Blast barriers are normally multilayer structures made of advanced composite laminates and optical interlayers [30]. An example of a blast barrier from the AH-64 Apache is illustrated in Figure 25.

Figure 25: PPG AH-64 Blast Barrier (Advanced Composite Laminate Plies, Urethane Interlayers) [27].

2.4 Manufacturers

Examples of transparency manufacturers include the following:

- Control Logistics, Inc.

- For more information, see the following link: http://www.aerowindows.com/index.php/manufacture/product [31].

- Gentex Corp.

- For more information, see the following link: http://www.gentex.com/aerospace/aircraft-windows [32].

- GKN Aerospace Transparency Systems.

- For more information, see the following link: http://www.gkn.com/en/our-divisions/gkn-aerospace/our-solutions/aftermarket-services-mro/transparancies-services [33].

- Nordam

- For more information, see the following link: http://www.nordam.com/products-services/commercial-aircraft [34].

- Perkins Aircraft Windows.

- For more information, see the following link: http://perkinsaircraft.com/index.html [35].

- PPG Aerospace Transparencies (Swedlow has been merged with PPG).

- For more information, see the following link: http://www.ppgaerospace.com/Products/Transparencies.aspx [24].

- TBM Glass.

- For more information, see the following link: https://tbmglass.com/aerospace [36].

- TEXSTARS Transparencies.

- For more information, see the following link: http://texstars.com/transparencies-2 [37].

3.0 DTIC Search

DSIAC staff searched the DTIC Research and Engineering (R&E) Gateway for any documents related to aircraft canopy materials and testing. The search yielded at least 22 potentially relevant results; however, many of the reports were limited distribution. To keep this report at a public distribution level, the DTIC search results are not included. Nonetheless, those with access to limited distribution reports are encouraged to conduct a search of DTIC’s R&E Gateway on the topic of aircraft transparency materials and testing.

4.0 Aircraft Transparency Data Sheets

The following data sheets were sent to the inquirer as attachments:

- “Windshields: Fairchild (Boeing) A-10” [14].

- “Windshields: Boeing F-15” [12].

- “Canopy Transparencies: Lockheed Martin F-16” [11].

- “Windshields: F/A-18 Hornet and Super Hornet” [13].

- “Cockpit Windows: Airbus A300/310/330/340” [38].

- “Cockpit Windows: Airbus A318/319/320/321” [39].

- “Cockpit Windows: Next Generation 737, Classic 737, 727, 707 Airplanes” [40].

- “Cockpit Windows: 717, DC-9, MD-80, MD-90 Airplanes” [16].

- “Cockpit Windows: 747-100/200/300/400 Airplanes” [41].

- “Cockpit Windows: 787 Airplanes” [17].

- “Cockpit Windows: DC-10/MD-11 Airplanes [15].

- “Cockpit Windows: Embraer EMB 120 Brasilia, ERJ 135, ERJ 140, ERJ 145 and ERJ 145XR” [19].

- “Cockpit and Passenger-Cabin Windows: Gulfstream G100/Astra SPX” [42].

- “Cockpit Windows: Bombardier Dash 8/Q-Series” [22].

- “Windshields and Windows: Lockheed Martin C-130” [20].

- “Windshields and Windows: Alenia Aermacchi C-27J Spartan, G222” [3].

- “Windshields: Lockheed Martin P-3 Orion” [21].

- “Windshields Piaggio P.180” [23].

- “Windshields, Windows, Canopy and Blast Barrier: Boeing AH-64 Apache” [27].

- “Windshields: Being CH-47 Chinook” [25].

- “Windshields and Central Panels: Sikorsky CH-53 Sea Stallion Helicopter” [26].

- “Windshields and Windows: Sikorsky S-92® Helicopter” [29].

- “Windshields: Sikorsky Black Hawk” [43].

- “Windshields and Windows: V-22 Osprey” [28].

References

[1] Merkel, H. S., and H. L. Task. “An Illustrated Guide of Optical Characteristics of Aircraft Transparencies.” AAMRLTR-89-015, Wright-Patterson AFB, OH, Armstrong Aerospace Medical Research Laboratory, 1989, http://www.dtic.mil/dtic/tr/fulltext/u2/a214565.pdf, accessed June 2017.

[2] Armstrong Flight Research Center. “File:Northrop T-38A Talon 3-side view.png.” EG-0111-01, U.S. National Aeronautics and Space Administration (NASA ), https://en.wikipedia.org/wiki/Northrop_T-38_Talon#/media/File:Northrop_T-38A_Talon_3-side_view.png, June 2016.

[3] PPG Aerospace. “Windshields and Windows: Alenia Aermacchi C-27J Spartan, G222.” Technical Data, http://www.ppgaerospace.com/getmedia/83375107-4f13-4f7b-8b7f-a6e4ca8f3b1a/C-27J_TD.pdf.aspx?ext=.pdf, accessed June 2017.

[4] Beidel, E. “Cutting F-35 Manufacturing Costs, Time Earns ONR Top Award.” Office of Naval Research, Arlington, VA, https://www.onr.navy.mil/en/Media-Center/Press-Releases/2014/ ManTech-F-35-Manufacturing-Award, 2 December 2014.

[5] PPG Industries, Inc. “Military Aviation: AH-64 Apache.” http://www.ppgaerospace.com/ Products/ Transparencies/ Military-Aviation/Boeing-AH-64-Apache.aspx, accessed June 2017.

[6] Bement, L. J. “Explosive Fracturing of an F-16 Canopy for Through-Canopy Crew Egress.” NASA Langley Research Center, 38th Annual SAFE Symposium, Reno, Nevada, https://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/20000109968.pdf, 9 October 2000.

[7] Designer Home. “General Dynamics (Lockheed) F-16 Fighting Falcon: Airframe Details and Overall Versions F-16A / MLU / F-16C,” http://designer.home.xs4all.nl/aircraft/af-16/af16-1.htm, June 2016.

[8] GlobalSecurity.org. “F-22 Raptor Cockpit,” https://www.globalsecurity.org/military/systems/ aircraft/f-22-cockpit.htm, accessed June 2017.

[9] Newman, K., SrA. “Aircrew Egress: The Last Lifeline,” 633rd Air Base Wing Public Affairs, http://www.jble.af.mil/News/Features/Display/Article/844768/, 13 June 2014.

[10] Wikimedia Commons, https://commons.wikimedia.org/wiki/Main_Page, accessed June 2017.

[11] PPG Aerospace. “Canopy Transparencies: Lockheed Martin F-16.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/e0bb783f-6b89-4a0e-9aaa-00775e599db4/F-16_tb.pdf.aspx?ext=.pdf, Fall 2008.

[12] PPG Aerospace. “Windshields: Boeing F-15.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/46f4abdf-53af-4e32-a11d-9c16bcea5707/boeing_F-15_tb_final.pdf?ext=.pdf, 2011.

[13] PPG Aerospace. “Windshields: F/A-18 Hornet and Super Hornet.” Technical Data, http://www.ppgaerospace.com/getmedia/331b1544-9a55-4721-bf8f-31ad996d95f2/F18_TD.pdf.aspx?ext=.pdf, accessed June 2017.

[14] PPG Aerospace. “Windshields: Fairchild (Boeing) A-10.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/12db0065-4386-4dff-af1c-caa3e65821b3/a-10_tb.pdf?ext=.pdf, Fall 2008.

[15] PPG Aerospace. “Cockpit Windows: DC-10/MD-11 Airplanes.” Technical Data, http://www.ppgaerospace.com/getmedia/e4a61e97-4e9b-4b83-b656-7eff3f53aac3/DC-10_TD_FINAL.pdf.aspx?ext=.pdf, accessed June 2017.

[16] PPG Aerospace. “Cockpit Windows: 717, DC-9, MD-80, MD-90 Airplanes.” Technical Data, http://www.ppgaerospace.com/getmedia/0b74bbcd-8484-4a94-bfb4-da3d3c841e46/ 717_TD_FINAL.pdf?ext=.pdf, accessed June 2017.

[17] PPG Aerospace. “Cockpit Windows: 787 Airplanes.” Technical Data, http://www.ppgaerospace.com/getmedia/926cb26f-e047-477d-b604-62d079f494bc/ B787_TD_FINAL.pdf.aspx?ext=.pdf, accessed June 2017.

[18] PPG Aerospace. “Cockpit Windows Airbus A330 Family (All CEO and NEO Models).” Technical Data Sheet, http://www.ppgaerospace.com/getmedia/56d5c311-a8be-4e90-9bc8-ceca69dc372e/tb_a300_fall05_1.pdf?ext=.pdf, accessed June 2017.

[19] PPG Aerospace. “Cockpit Windows: Embraer EMB 120 Brasilia, ERJ 135, ERJ 140, ERJ 145 and ERJ 145XR.” Technical Data, http://www.ppgaerospace.com/getmedia/b039ee0b-5992-47b1-8bb2-6c42a667389a/Embraer_EMB120-ERJ135_Final_Web.pdf.aspx?ext=.pdf, accessed June 2017.

[20] PPG Aerospace. “Windshields and Windows: Lockheed Martin C-130.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/57012ee5-b60d-4edf-ba71-c07119075830/ C-130_tb_final.pdf?ext=.pdf, 2011.

[21] PPG Aerospace. “Windshields: Lockheed Martin P-3 Orion.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/263a2a28-3a09-4f91-9254-8de56e4a35cb/ Lockheed_Martin_P-3_Orion_TB_final.pdf?ext=.pdf, 2011.

[22] PPG Aerospace. “Cockpit Windows: Bombardier Dash 8/Q-Series.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/d32c1259-6f6b-49ba-86b6-a541dfcf279f/ Dash8_tb_summer2008.pdf.aspx?ext=.pdf, Summer 2018.

[23] PPG Aerospace. “Windshields Piaggio P.180.” Technical Data, http://www.ppgaerospace.com/getmedia/ef9f7cd1-c95d-41d0-921b-6c671eac0c07/ piaggio_P180_v5-2013.pdf?ext=.pdf, October 2013.

[24] PPG Aerospace. “Aerospace Transparencies.” http://www.ppgaerospace.com/Products/ Transparencies.aspx, accessed June 2017.

[25] PPG Aerospace. “Windshields: Being CH-47 Chinook.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/2fe473e8-c25b-425c-b09e-1de7c164ef65/ boeing_chinook_CH-47_final.pdf.aspx?ext=.pdf, April 2011.

[26] PPG Aerospace. “Windshields and Central Panels: Sikorsky CH-53 Sea Stallion Helicopter.” Technical Data, http://www.ppgaerospace.com/getmedia/9f42cdcf-9e15-423d-b80d-bda9fa9f86de/Sikorsky_CH53_TD.pdf.aspx?ext=.pdf, accessed June 2017.

[27] PPG Aerospace. “Windshields, Windows, Canopy and Blast Barrier: Boeing AH-64 Apache.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/ee7a2a11-6fee-4d0f-ad60-d9202c2ca896/boeing_apache_AH-64_final.pdf.aspx?ext=.pdf, April 2011.

[28] PPG Aerospace. “Windshields and Windows: V-22 Osprey.” Technical Data, http://www.ppgaerospace.com/getmedia/2d48477d-2717-48ec-ae7b-c2cdf4a1238b/V-22_TD.pdf.aspx?ext=.pdf, accessed June 2017.

[29] PPG Aerospace. “Windshields and Windows: Sikorsky S-92® Helicopter.” Technical Data, http://www.ppgaerospace.com/getmedia/762c3d72-0163-4789-b115-f0f7db092b02/S-92_TD.pdf.aspx?ext=.pdf, accessed June 2017.

[30] PPG Industries, Inc. “Windshields, Windows, Canopy and Blast Barrier.” http://www.ppgaerospace.com/getmedia/ee7a2a11-6fee-4d0f-ad60-d9202c2ca896/ boeing_apache_AH-64_final.pdf.aspx?ext=.pdf, accessed June 2017.

[31] Control Logistics. “Products Showcase.” http://www.aerowindows.com/index.php/ manufacture/product, accessed June 2017.

[32] Gentex Corporation. “Aircraft Windows.” http://www.gentex.com/aerospace/aircraft-windows, accessed June 2017.

[33] GKN. “Transparencies Aftermarket Services.” https://www.gkn.com/en/our-divisions/gkn-aerospace/our-solutions/aftermarket-services-mro/transparancies-services, accessed June 2017.

[34] Nordam. “For Commercial Aircraft.” http://www.nordam.com/products-services/ commercial-aircraft, accessed June 2017.

[35] Perkins Aircraft. http://perkinsaircraft.com/index.html, accessed June 2017.

[36] TBM Glass. “Aerospace and Defense Glass.” https://tbmglass.com/aerospace/, accessed June 2017.

[37] TEXSTARS. “Transparencies.” http://texstars.com/transparencies-2/, accessed June 2017.

[38] PPG Aerospace. “Cockpit Windows: Airbus A300/310/330/340.” Transparency Bulletin, Fall 2005.

[39] PPG Aerospace. “Cockpit Windows: Airbus A318/319/320/321.” Technical Data.

[40] PPG Aerospace. “Cockpit Windows: Next Generation 737, Classic 737, 727, 707 Airplanes.” Technical Data, http://www.ppgaerospace.com/getmedia/ba64914b-c114-46bb-8cc4-c2ab09d440ee/B737_TD_FINAL.pdf.aspx?ext=.pdf, accessed June 2018.

[41] PPG Aerospace. “Cockpit Windows: 747-100/200/300/400 Airplanes.” Technical Data, http://www.ppgaerospace.com/getmedia/72a856f3-0152-43f5-bb34-ce873a8f329a/747_TD_FINAL.pdf.aspx?ext=.pdf, accessed June 2017.

[42] PPG Aerospace. “Cockpit and Passenger-Cabin Windows: Gulfstream G100/Astra SPX.” Technical Data, http://www.ppgaerospace.com/getmedia/1e79d41e-ca11-4311-93f7-922a30071ce9/gulfstream_G100_v4-2013.pdf?ext=.pdf, October 2013.

[43] PPG Aerospace. “Windshields: Sikorsky Black Hawk.” Transparency Bulletin, http://www.ppgaerospace.com/getmedia/994a4cd1-c772-4615-a2c7-f881babd91d2/sikorsky_black_hawk_final.pdf?ext=.pdf, April 2011.

[44] LaPuma, P. T., and J. C. Bridenbaugh. “Specifications and Measurement Procedures and Aircraft Transparencies.” AAMRL-TR-88-058, Wright-Patterson AFB, OH, Armstrong Aerospace Medical Research Laboratory, 1988, DTIC No. ADA209396.

Appendix A: U.S. DoD Attack, Fighter, and Bomber Aircraft Transparency Materials

Additional details on the transparency shape and layer structure can be found in the 1988 report, “Specifications and Measurement Procedures and Aircraft Transparencies,” [44] from which the information in Table A-1 was extracted. Since 1988, however, many new plastics, composites, and glass formulations have been developed that enhance strength, durability, impact resistance, and optical properties. These new transparency formulations may have changed in terms of number of layers and the type of material used for both the core layers and interlayer bonding material and outer and inner layer coatings (especially for the case of aftermarket replacement transparencies). In addition, a given transparency design may be different with respect to layers and materials based on the manufacturer providing it or for the design intent (e.g., difference in F-16 350-knot standard canopy or 550-knot bird-strike-resistant canopy).

Table A-1: U.S. Department of Defense (DoD) Attack, Fighter, and Bomber Aircraft Transparency Materials [44]

| Transparency Type | Manufacturer | Shape | Structure | Ply #, IL or C* |

Material Type (outer to inner) |

Thickness (inches) |

| A-7D/K | ||||||

| Windshield | Proposed Design | Compound Curved | Plastic Laminate | 1 | Cast Acrylic | 0.125 |

| IL | Urethane | 0.030 | ||||

| 2 | Polycarbonate | 0.250 | ||||

| IL | Urethane | 0.030 | ||||

| 3 | Polycarbonate | 0.250 | ||||

| IL | Urethane | 0.030 | ||||

| 4 | Cast Acrylic | 0.125 | ||||

| Canopy, Fwd | Swedlow | Compound Curved | Acrylic & Glass Laminate | 1 | Stretched Acrylic | 0.1875 |

| A-7D | ||||||

| Center Windshield | PPG | Flat | Glass Laminate | 1 | Semi-temper Glass | 0.250 |

| IL | Polyvinyl Butyral | 0.040 | ||||

| 2 | Semi-temper Glass | 0.250 | ||||

| IL | Polyvinyl Butyral | 0.020 | ||||

| 3 | Full-Temper Glass | 0.250 | ||||

| IL | Polyvinyl Butyral | 0.020 | ||||

| 4 | Full-Temper Glass | 0.250 | ||||

| IL | Polyvinyl Butyral | 0.020 | ||||

| 5 | Full-Temper Glass | 0.250 | ||||

| Canopy | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.1875 |

| Side Sindshield | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.250 |

| A-10A | ||||||

| Canopy | Swedlow | Compound Curved | Monolithic Acrylic | C | Nylon Fabric | 0.060 |

| 1 | Stretched Acrylic | 0.250 | ||||

| C | Nylon Fabric | 0.060 | ||||

| Windshield | PPG | Flat | Glass Laminate | 1 | Semi-temper Glass | 0.187 |

| IL | Polyvinyl Butyral | 0.080 | ||||

| 2 | Full-Temper Glass | 0.375 | ||||

| IL | Polyvinyl Butyral | 0.040 | ||||

| 3 | Full-Temper Glass | 0.375 | ||||

| IL | Polyvinyl Butyral | 0.080 | ||||

| 4 | Light-Temper Glass | 0.125 | ||||

| Side Panel | PPG | Compound Curved | Plastic Laminate | 1 | Cast Acrylic | 0.020 |

| IL | Polyurethane | 0.030 | ||||

| 2 | Polycarbonate | 0.156 | ||||

| IL | Polyurethane | 0.030 | ||||

| 3 | Polycarbonate | 0.156 | ||||

| IL | Polyurethane | 0.030 | ||||

| 4 | Cast Acrylic | 0.080 | ||||

| B-1B | ||||||

| Windshield | Rockwell | Compound Curved | Glass & Plastic Laminate | 1 | Tempered Glass | 0.120 |

| IL | Silicone | 0.235 | ||||

| 2 | Polycarbonate | 0.870 | ||||

| IL | Silicone | 0.120 | ||||

| 3 | Polycarbonate | 0.180 | ||||

| C | Protective Coating | — | ||||

| F-5A, F-5E | ||||||

| Windshield | Northrop Corp. | Curved Conical | Monolithic Acrylic | 1 | Stretched Acrylic | 0.710 |

| Canopy | Northrop Corp. | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.250 |

| F-14A | ||||||

| Windshield | PPG | Flat | Glass Laminate | 1 | Semi-temper Glass | 0.187 |

| IL | Polyvinyl Butyral | 0.060 | ||||

| 2 | Full-Temper Glass | 0.500 | ||||

| IL | Polyvinyl Butyral | 0.080 | ||||

| 3 | Full-Temper Glass | 0.250 | ||||

| IL | Polyvinyl Butyral | 0.060 | ||||

| 4 | Annealed Glass | 0.500 | ||||

| IL | Polyvinyl Butyral | 0.020 | ||||

| 5 | Annealed Glass | 0.250 | ||||

| Canopy, Fwd | Swedlow | Curved Conical | Acrylic Laminate | 1 | Cast Acrylic | 0.125 |

| IL | Silicone | 0.100 | ||||

| 2 | Stretched Acrylic | 0.300 | ||||

| Canopy, Aft | Swedlow | Compound Curved | Acrylic Laminate | 1 | Cast Acrylic | 0.100 |

| IL | Silicone | 0.100 | ||||

| 2 | Stretched Acrylic | 0.200 | ||||

| Side Quarter Panels | Swedlow | Compound Curved | Acrylic Laminate | 1 | Cast Acrylic | 0.125 |

| IL | Silicone | 0.100 | ||||

| 2 | Stretched Acrylic | 0.300 | ||||

| F-15 | ||||||

| Windshield | Swedlow | Curved Conical | Monolithic Acrylic | 1 | Stretched Acrylic | 0.900 |

| Canopy, Fwd | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.300 |

| Canopy, Aft | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.300 |

| F-16A/B/C/D | ||||||

| Canopy, Fwd | Goodyear | Compound Curved | Plastic Laminate | 1 | PLEX II Acrylic | 0.130 |

| IL | Polyurethane | 0.300 | ||||

| 2 | Polycarbonate | 0.187 | ||||

| IL | Polyurethane | 0.300 | ||||

| 3 | Polycarbonate | 0.187 | ||||

| IL | Polyurethane | 0.300 | ||||

| 4 | PLEX II Acrylic | 0.120 | ||||

| Canopy, Fwd | TEXSTAR | Compound Curved | Plastic Laminate | 1 | PLEX II Acrylic | 0.125 |

| IL | Polyurethane | 0.060 | ||||

| 1 | Polycarbonate | 0.500 | ||||

| Canopy, Fwd | Sierrancin | Compound Curved | Plastic Laminate | 1 | PLEX II Acrylic | 0.125 |

| IL | Silicone | 0.300 | ||||

| 2 | Polycarbonate | 0.500 | ||||

| F-16A/B/C/D (Canopy Being Evaluated for Improved Bird Strike Performance) | ||||||

| Canopy, Fwd | TEXSTAR | Compound Curved | Monolithic Polycarbonate | 1 | Polycarbonate | 0.750 |

| Canopy, Aft | TEXSTAR | Curved Conical | Monolithic Polycarbonate | 1 | Polycarbonate | 0.250 |

| F/A-18L | ||||||

| Windshield | Swedlow | Curved Conical | Monolithic Acrylic | 1 | Stretched Acrylic | 0.600 |

| Canopy, Single-Seat | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.250 |

| Canopy, 2-Seat, Fwd Piece | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.350 |

| Canopy, 2-Seat, Aft Piece | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.350 | |

| F-111/FB-111 | ||||||

| Windshield | Sierracin, PPG, Swedlow | Curved Conical | Plastic Laminate | 1 | Stretched Acrylic | 0.125 |

| IL | — | 0.060 | ||||

| 2 | Polycarbonate | 0.250 | ||||

| IL | — | 0.030 | ||||

| 3 | Polycarbonate | 0.250 | ||||

| Canopy | Sierracin, PPG, Swedlow | Compound Curved | Plastic Laminate | 1 | Stretched Acrylic | 0.125 |

| IL | — | 0.060 | ||||

| 2 | Polycarbonate | 0.125 | ||||

| IL | — | 0.030 | ||||

| 3 | Polycarbonate | 0.125 | ||||

| T-37/A-37 | ||||||

| Canopy, Fwd Pieces | Cesna | Compound Curved | Plastic Laminate | 1 | Cast Acrylic | 0.080 |

| IL | — | 0.030 | ||||

| 2 | Polycarbonate | 0.190 | ||||

| IL | — | 0.030 | ||||

| 3 | Polycarbonate | 0.190 | ||||

| IL | — | 0.030 | ||||

| 4 | Polycarbonate | 0.080 | ||||

| Canopy, Aft Piece | Cesna | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.250 |

| T-38 | ||||||

| Windshield | PPG | Curved Conical | Polycarbonate Laminate | C | PPG 5300 Outer Liner | — |

| 1 | Polycarbonate | 0.375 | ||||

| IL | PPG 112 | — | ||||

| 2 | Polycarbonate | 0.187 | ||||

| C | PPG 8500 Coating | — | ||||

| Windshield, Instructor | Swedlow | Flat | Monolithic Polycarbonate | 1 | Polycarbonate | 0.500 |

| T-38 (Older Configuration) | ||||||

| Windshield | Sierrancin | Curved Conical | Monolithic Acrylic | 1 | Stretched Acrylic | 0.600 |

| Winshield, Instructor | Swedlow | Flat | Monolithic Acrylic | 1 | Stretched Acrylic | 0.400 |

| Canopy, Fwd | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.250 |

| Canopy, Aft | Swedlow | Compound Curved | Monolithic Acrylic | 1 | Stretched Acrylic | 0.400 |

Want to find out more about this topic?

Request a FREE Technical Inquiry!