an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

Nondestructive, Reusable Bullet Trap Systems

Posted on October 3, 2019 | Completed on October 3, 2019 | By: Scott E. Armistead, Kevin Mcardle, Doyle T. Motes III

Are there reusable bullet catchers that do not damage the projectile?

The inquirer currently uses stacks of ceiling tiles to collect projectiles that have penetrated test articles and asked the Defense Systems Information Analysis Center (DSIAC) for an alternative that would allow the same fast projectile recovery and test event completion but without the excessive dust and having to purchase a large amount of ceiling tiles for each test. A DSIAC vulnerability subject matter expert with experience developing warhead fragment catch media systems recommended a fiberboard used by U.S. Department of Defense and commercial warhead test ranges. DSIAC also performed open-source and Defense Technical Information Center Research and Engineering Gateway research on various bullet trap construction techniques and materials used to support gun bullet forensics and nondestructive recovery of experimental bullets. From the information and technical reports found, recommendations were provided on self-built and commercially available systems. In addition, the development and testing of reusable, soft-catch bullet traps for small- to medium-caliber ammunition and materials used in catch systems were then described. Finally, DSIAC contacted NTS-Chesapeake Testing, which specializes in fully accredited, ballistic-resistant material impact testing and ammunition and firearms testing, for their recommendations on bullet retrieval. The compiled information and recommendations were delivered to the inquirer.

1.0 Introduction

The Defense Systems Information Analysis Center (DSIAC) was asked to assist with performing research on small-caliber projectile catch media and systems that do not damage the projectile, are reusable, and do not produce significant dust.

DSIAC weapon systems, ballistic vulnerability, and advanced materials research, development, testing, and analysis subject matter experts (SMEs) discussed the issue [1]. The SMEs have extensive experience in design and development of warhead testing arenas, fragment catch media, and small fragment/projectile forensics. For performing detailed forensics analysis, the consensus was that the use of fragment catch media such as fiberboard used by many of the Department of Defense (DoD) and commercial warhead test ranges, although suitable for harder materials such as steel, titanium, and tungsten, may not support nondestructive catch and forensics for fragments or projectiles made of softer materials such as lead or copper or those coated with such materials.

DSIAC staff performed open-source research for information on various conventional bullet-trap construction techniques and materials used to support small-caliber firearms bullet forensics and nondestructive recovery of experimental, small-caliber ammunition projectiles. The SMEs also searched the Defense Technical Information Center Research and Engineering (DTIC R&E) Gateway for information on nondestructive bullet-trap development and testing and reviewed a technical report with information on the successful development and testing of a reusable, soft-catch bullet trap for small- to medium-caliber ammunition. In addition, the SMEs reviewed the materials used in the catch medium to provide information on them and possible alternatives.

The SMEs also researched potential use of nonconventional bullet capture techniques such as interacting magnetic/electrical fields and formation of eddy currents to slow down/stop bullets and use of aerogel as a capture media. The U.S. Army previously conducted research in this area and a prototype system was developed by industry. However, very high magnetic fields are required to stop a projectile in a reasonable distance and may result in unacceptable heating of the projectile. Additionally, the system, associated high-power electronics, and further development may not be cost effective for this particular application. Research on aerogels by NASA indicated that hundreds of times the length of the projectile is needed to capture extremely small, low-mass particles with little kinetic energy, likely resulting in an unacceptable amount of aerogel material required to stop small-caliber bullets.

Finally, NTS-Chesapeake Testing, a DoD-certified testing facility that specializes in fully accredited, ballistic-resistant material projectile impact and penetration testing, was consulted to verify our findings. Observations and recommendations are provided.

2.0 Standard Destructive Projectile Catch Methodologies

DSIAC SMEs were familiar with standard ammunition projectile-recovery methodologies based on water traps, snail traps (circular deceleration traps), granulated rubber fill traps, sand traps, dry or wet paper fill traps (stacked cardboard, magazines, etc.), and the like. These traps are not deemed suitable for performing forensic testing of softer metal (e.g., aluminum, copper, or lead) nor generally for harder-metal (e.g., steel, titanium, or tungsten) small-caliber ballistic projectiles with significant velocities in the range of modern combat small arms. These recovery methods are likely to cause significant marring, deformation, and fragmentation for most small-arms ammunition calibers at expected operational use velocities. Ballistic gels (including the reusable gels) can also damage the bullet similarly to how flesh does. Hollow-point and frangible ammunition projectiles will break apart in most of these recovery media. (Some traps based on granulated rubber have been shown to successfully catch hollow-point bullets without them breaking apart.) However, if detailed forensics are not required, and marring and obscuration of barrel/rifling markings on the projectile will not be issues, or if the projectiles are fired at reduced propellant loads producing significantly less-than-normal velocities, then some of these methods (e.g., granulated rubber fill and stacked cardboard) may work [1].

Although DSIAC SMEs do not recommend any of these projectile catch systems for the inquirer’s described requirements, their design and construction techniques that have been shown to catch projectiles effectively and safely can be considered. For example, in a 1996 U.S. Army Environmental Center technology feasibility assessment of bullet traps for Army ranges, researchers reviewed 11 friction, 5 impact, and 3 deceleration trap systems for their ability to effectively and safely catch up to .50-caliber projectiles [2]. Catch materials/methodologies reviewed include rubber granules, recycled tire granules, solid rubber blocks, shredded tires bonded in blocks, stacked tires, conveyor belt strips, wax or polyurethane blocks, polymer elastic, elastomeric granular screen, wooden ties or logs, shock-attenuating concrete, Linatex front material with armor backing, a sand box with an angled plate, a water trough with an angled plate, and helical chambers.

3.0 DoD and Commercial Warhead Range Fragment Catch Materials

Like the requestor’s noted use of ceiling tiles as a catch medium, many DoD and commercial warhead test ranges use bundles/layers of commercial fiberboard wall insulation panels. These are plant cellulose fiber-based products (such as wood fibers) combined with a binder and a water-resistive coating or component (such as paraffin). In DSIAC SME collective experience, these products successfully catch aluminum, copper, steel, titanium, and tungsten fragments without damaging them. In bulk, the product would likely be cheaper than ceiling tiles. However, like the ceiling tiles, they do create a lot of dust/particle residue due to fragment impact and also generate dust when the layers are broken apart to look for the fragments (or bullets). Dr. Kevin McArdle, a DSIAC warhead arena, gas-gun development, and vulnerability analysis SME, noted that from his experience the fiberboard panel recovery method would deform soft lead projectiles (especially non-steel jacketed projectiles) and fragment hollow-point projectiles [1].

4.0 Nondestructive Self-Made Bullet Traps

Sections 4.1 and 4.2 describe some potential nondestructive bullet recovery solutions that can be manually constructed.

4.1 Flour- or Sawdust-Based Bullet Traps

Some forum discussions on recovering experimental bullets mention the use of a long trap box with thin cardboard separators about a foot apart with the space between the separators filled with either flour or lightly oiled sawdust. However, the DSIAC SMEs in their research did not find any documentation of test results from using such traps. These traps would also likely create significant dust like what occurs with the ceiling tile method.

4.2 Cotton Fiber-/Waste- or Ballistic Fiber-Based Bullet Traps

There is some discussion citing success of recovery with no/minimal bullet damage by using a long tube or box (8−12 ft long) filled with Dacron pillow stuffing. The claim is that the Dacron forms a cocoon around the bullets as it passes through and eventually brings them to a fairly gentle stop. Cited results note that for a soft lead bullet, there would be some minor imprinting of the Dacron fibers on the bullet nose, but the bullet would otherwise be in pristine condition. A .22 long rifle round would stop within 4−5 ft, and a centerfire rifle round would stop in approximately 10 ft. However, when shotgun slugs were used, a few did impact the side of a 4-inch-wide trap, but switching to a 12-inch-wide trap solved the issue. As the bullet becomes wrapped in a Dacron cocoon, it’s hard to find visually, but a simple metal detector can be used to locate it [3].

Similarly, another forum described the use of cotton waste in the early days of ballistics research related to tracing rifling marks. A fiberfill product was used which performed similarly to the Dacron. The fiberfill quickly wraps around the projectile and increases its size until it stops. The trap was successfully used to recover 12-gauge Lyman pellet style slugs and 158-grain, .357-cal bullets fired from a .357 Maximum Contender with a 10-inch barrel. The fiberfill cocoon that formed around the .357 slugs was approximately 3 inches in diameter [4]. Although the type of fiberfill product was not mentioned, an Internet search for fiberfill indicated it comes in both nonorganic and organic forms such as polyester, polylactic acid (PLA), carded scoured wool, raw cotton, kapok tree fibers, etc. Any of these materials would be inexpensive, reusable, and should not create nearly as much dust as the ceiling tiles. Most of the literature found in the search noted the use of cotton fiber/cotton waste.

In an Association of Firearm and Tool Mark Examiners (AFTE) forum related to forensic bullet traps, one of the members noted that an AFTE Journal article [5] by Nancy McCombs of the California State Department of Justice provides plans for an inexpensive, cotton-filled, sewer pipe-based trap. The AFTE member made one similar to that described in the article and had “good luck producing high-quality, test-fired bullets from handguns and rifles.” He also noted that the lab where he worked used cotton traps and that the key to avoiding burnishing/polishing of the bullets (that would mute the markings) was to ensure that the cotton was packed tightly. He further described designing one with a hand-cranked piston at the back of the trap to pack the cotton but found that using the piston could result in the cotton being packed too tightly [6].

In a document by the Indiana State Police describing test methods used in their Forensic Firearms Identification Unit, it was suggested that when using a cotton-waste recovery box, the examiner should consider placement of paper partitions at various points in the box to help with tracking and locating the bullet. (Each piece of paper can be easily examined to determine how far the bullet has penetrated into the catch material.) [7].

5.0 Nondestructive Commercial Forensic Bullet Traps

There are commercially available bullet traps designed to cause minimal damage to the bullet to allow forensic analysis. An example is the Forensic Buddy that uses a media made of small rubber spheres with a capsule in the center [8]. The system catches hollow-point bullets without causing them to break apart. However, comments on the AFTE forum about the Forensic Buddy by the Syracuse, NY Onondaga County Center for Forensic Sciences noted that when compared to bullets shot into a water trap, the bullets recovered from the Forensic Buddy had “muted” markings that were not as distinct as those shot into a water tank [9, 10].

These comments were seconded by a firearm examiner at the Arizona Department of Public Safety that had years of experience in using the Forensic Buddy. He noted that the problem seemed to be exacerbated after extended use of the trap when the small rubber spheres are dirty. He also noted that he was more impressed with the use of shredded ballistic fiber (Kevlar) traps. This trap would be similar to the self-made Dacron and cotton fiber-based traps discussed in Section 4.2. The examiner also noted that the ballistic fiber trap was better at limiting bullet deformation and did not have any downside with respect to the quality of the bullet marks [11]. Muted markings may not be a concern to those who are not involved with forensics related to bullet markings.

A post by the Utah Department of Public Safety [12] notes that their forensic scientists shoot into a ballistic fiber (Kevlar) trap and that, “Using this trap helps us capture full power rifle bullets in a better condition than the water tank. With the water tank, full power shots from a rifle tend to break the bullet into little pieces. The Kevlar trap catches the high-velocity bullets with less damage and distortion.” The Safari Land Group website [13] provides additional information on ballistic fiber traps.

Only one commercially available system was found that could recover a small-caliber projectile at the top of the mass/velocity range like a Browning Machine Gun .50 cal (BMG 50): the CyberNational Bullet Recovery System [14]. The manufacturer, CyberNational Inc., claims certification for safely catching these types of rounds.

This is a water tank-based recovery system that would likely damage the round. However, a ballistic fiber-based trap could be built long enough to catch the high-velocity round, and the design could be optimized through testing and experimentation. Key concerns would be in proper selection and packing of the catch media as noted in Section 4.2 and in designing the system to ensure that the projectile does not “porpoise” out of the catch trap as noted in Section 6.0 where fragments were deflected by variations in density of the packing material and exited the sides of the bullet catch media boxes.

6.0 Rock Island Arsenal Soft-Catch System Testing

DSIAC staff searched the DTIC R&E Gateway and found a report by the Rock Island Arsenal from 1976 [15] that discusses a method of building a soft-catch trap for small- and medium-caliber projectiles that allows recovery of most projectiles in an undamaged condition. (The soft-catch trap is soft enough that the barrel etchings on the projectile rotating bands are not altered.) Testing proved that the system could successfully catch 7.62-mm and 20-mm projectiles with very little to no damage. The system also performed well with 30-mm projectiles; however, some of the soft ogives on the front of the 30-mm rounds were broken into fragments.

The catch medium is a 50/50 mixture of Vermiculite plus styrene foam insulation and sawdust placed in medium-sized cartons (12 × 28 × 36 inches). The cartons can be used for repeated firings. Once the projectiles are removed, penetrated cartons can be reused by simply taping over the holes. However, the authors did note that projectiles or fragments could exit the material. They further noted that the cartons had to be handled/placed somewhat gently as jarring impacts can vary the density of the mixture in the boxes by compacting the mixture at one end of the cartons. This density variation can deflect projectiles causing them to exit out of the sides of the cartons. Unless the setup is placed in an enclosed range where personnel/ equipment are not in the hazard area, a containment area should be built for using the boxes of material [15].

Vermiculite is a naturally occurring, lightweight mineral compound (hydrated laminar magnesium-aluminum-iron silicate), which is compressible and has a low hardness (Mohs hardness1 between 1 and 2). Exfoliated vermiculite has a density of between 60 and 160 kg/m3. It is available as a gardening product in various coarseness grades [16, 17]. The cost of vermiculite is approximately $35 for 4 ft3; bulk quantities would be less. The report does not mention what coarseness was used in the testing, but a photograph in the report indicates that it was likely the medium or large coarseness [15]. An alternative might be organic perlite, which is a common substitute for vermiculite. The expanded form of perlite has a bulk density of 30−150 kg/m3. Perlite costs approximately the same as vermiculite [18].

1 Mohs hardness [is the] rough measure of the resistance of a smooth surface to scratching or abrasion, expressed in terms of a scale devised (1812) by the German mineralogist Friedrich Mohs. The Mohs hardness of a mineral is determined by observing whether its surface is scratched by a substance of known or defined hardness. To give numerical values to this physical property, minerals are ranked along the Mohs scale, which is composed of 10 minerals that have been given arbitrary hardness values [21].

7.0 Use of Electromagnetic Fields and Eddy Currents to Slow Down/Stop Projectiles

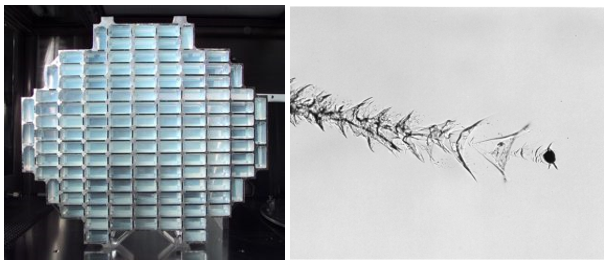

DSIAC SMEs noted the mention in several forums of potentially using interacting magnetic/electrical fields and formation of eddy currents to slow down/stop a bullet. Calculations were performed in the 1980s on this subject by Bennet et al. [19] and were extended by Texas Research Institute Austin, Inc. (TRI-Austin) in 2014 as part of a sizing study for an electromagnetic (EM) projectile brake as part of a response to the Army’s Rapid Innovation Fund topic to nondestructively brake a bullet (Figure 1, left). Any solution to this problem requires significant magnetic fields and very tight tolerances to allow the maximum inductive coupling of the fields into the bullet. One company (Sierra Lobo, Inc.) developed a product to magnetically brake a projectile as part of the work on the Phase II SBIR topic A092-049 – High-G Magnetic Capture System [20] (Figure 1, right). The company has a U.S. patent on this product (U.S. patent 8,237,526). The energies generated as part of stopping in a reasonable distance may result in unacceptable heating to the projectile, and due to the high-power electronics, such a system may be cost-prohibitive.

Figure 1: Sizing Study Results From TRI-Austin for the EM Inductive Braking of a 50-gm, 12.7-mm Projectile (Left); an EM Projectile Braking System From Sierra Lobo Developed From a Phase II SBIR Effort [20] (Right).

8.0 Aerogels

Aerogels are solid, rigid, and dry materials that do not resemble a gel in their physical properties. The name comes from the fact that they are made from gels. Their impressive load-bearing abilities are due to their dendritic microstructure, in which average-size spherical particles (2–5 nm) are fused into clusters. These clusters form a three-dimensional, highly porous structure of almost fractal chains, with pores just under 100 nm. The average size and density of the pores can be controlled during the manufacturing process.

Aerogel is a material that is 99.8% air. Aerogels have a porous, solid network that contains air pockets, which take up the majority of space within the material. The dearth of solid material allows aerogel to be almost weightless. NASA has previously successfully used aerogels as a mechanism on the Stardust spacecraft to capture micron-sized particles streaming off the comet Wild 2 for safe return to Earth for on-ground analysis (Figure 2, left) [22].

This system worked well for capturing the very small particles streaming off the comet. (Seven particles were identified with an estimated mass of 1 trillionth of a gram [23]. The average kinetic energy at impact of one of these particles is less than 1 mJ for an impact speed of 20 km/s). However, for a 50-gm projectile traveling at rifle velocities (approximately 1 km/s), the kinetic energy at impact is 25,000 J. Because the track paths into the aerogel for the cometary particles were on the order of 200 times their diameter, it is unlikely that aerogel will be suitable for use as a means for nondestructively stopping a bullet with a mass and impact energy that is orders of magnitude higher than the comet particles (further research would be needed to definitively determine this). Figure 2 (right) shows an image of a trail left behind in aerogel by a hypervelocity particle [24].

Figure 2: An Image of the Aerogel-Based Collector on the Stardust Spacecraft (Left); an Image of a Trail Left Behind in Aerogel by a Hypervelocity Particle [24] (Right).

9.0 NTS-Chesapeake Testing

DSIAC findings were discussed with ballistics testing experts at the NTS-Chesapeake Testing [25]. NTS-Chesapeake Testing specializes in fully accredited ballistic-resistant material impact testing and ammunition and firearms testing. It is one of the few labs certified by the National Institute of Justice to perform personal body-armor testing, and it is also certified by the U.S. Army Aberdeen Test Center to perform helmet and hard- and soft-armor testing. They did not know of other practical methods for successful, nondestructive bullet recovery than those mentioned in this report. They have experimented with a few alternatives, but none worked well.

References

[1] SURVICE Engineering Company. Senior Engineer. Personal communication, 1 October 2019.

[2] Evans, D., and R. Young. Bullet Trap Feasibility Assessment and Implementation Plan. U.S. Army Environmental Center. DTIC Accession Number ADA308438, March 1996.

[3] Dzupin, S. “Thread: Recovering Experimental Bullets.” Message #6. Practical Machinist. https://www.practicalmachinist.com/vb/gunsmithing/recovering-experimental-bullets-183786/, 23 June 2009.

[4] Johnson, J. “Thread: Recovering Experimental Bullets.” Message #10. Practical Machinist. https://www.practicalmachinist.com/vb/gunsmithing/recovering-experimental-bullets-183786/, 23 June 2009.

[5] McCombs, N. D. “The Cotton Pipe Recovery System.” The Association of Firearm and Tool Mark Examiners (AFTE) Journal, vol. 39, no. 4, pp. 323−329, 2007.

[6] Pearlson, N. “Topic: Forensic Buddy.” Reply #7. The Association of Firearm and Tool Mark Examiners (AFTE) Forums. https://forum.afte.org/index.php?topic=9575.0, 19 February 2014.

[7] Indiana State Police Laboratory Division. “Forensic Firearms Identification Unit Test Methods.” Version 14, https://www.in.gov/isp/labs/files/Firearms_and_Toolmarks_Test_Method.pdf, 1 July 2015.

[8] Savage Range Systems. “Bullet Traps & Clearing Stations.” https://www.savagerangesystems.com/content?p=traps, accessed 2 October 2019.

[9] Kurimsky, M. “Topic: Forensic Buddy.” Reply #1. The Association of Firearm and Tool Mark Examiners (AFTE) Forums. https://forum.afte.org/index.php?topic=9575.0, 12 February 2014.

[10] Harter, S. “Topic: Forensic Buddy.” Reply #4. The Association of Firearm and Tool Mark Examiners (AFTE) Forums. https://forum.afte.org/index.php?topic=9575.0, 18 February 2014.

[11] Brudenell, A. “Topic: Forensic Buddy.” Reply #5. The Association of Firearm and Tool Mark Examiners (AFTE) Forums. https://forum.afte.org/index.php?topic=9575.0, 18 February 2014.

[12] Utah Department of Public Safety. “One of our Forensic Scientists lines up to shoot a .30-06 caliber M1 Garand into a Kevlar bullet trap to collect pristine bullets for comparison to evidence specimens.” Facebook, https://www.facebook.com/UtahDPS/photos/a.10152760476257738/10155838110527738/?type=1&theater, 23 February 2017 (accessed 2 October 2019).

[13] Safariland Group. “Bullet Catcher Collection Chamber.” https://www.safariland.com/products/forensics/trajectory-and-ballistics/bullet-catcher-collection-chamber-1005748.html, 2 October 2019.

[14] CyberNational, Inc. “Forensics.” https://cyber-national.com/forensics/, accessed 2 October 2019.

[15] Hansen, J., W. Piehl, and H. Plude. “A Method for Retrieving Fired Projectiles During the Data Acquisition Test.” U.S. Army Armament Command, Aircraft & Air Defense Weapons Systems Directorate. Distribution A, DTIC Accession Number: ADA021630, 1 January 1976.

[16] The Vermiculite Association. “Exfoliated Vermiculite Data.” https://www.vermiculite.org/wp-content/uploads/2014/10/Exfoliated-Vermiculite-Data.pdf, October 2014.

[17] dupre Minerals. “Exfoliated Vermiculite.” https://www.dupreminerals.com/wp-content/uploads/2017/04/vermiculite-datasheet.pdf, April 2017.

[18] Wikipedia. “Perlite.” https://en.wikipedia.org/wiki/Perlite, accessed 2 October 2019.

[19] Bennett, J., T. Gora, P. J. Kemmey, and W. J. Holkert. “Electromagnetic Braking of a Metallic Projectile in Flight,” IEEE Transactions on Magnetics, vol. 21, no. 3, pp. 1250−1253, 1985.

[20] Sierra Lobo. “High-G Magnetic Capture.” https://www.sierralobo.com/engineered-systems/high-g-magnetic-capture/, accessed 3 June 2020.

[21] Encyclopedia Britannica. “Mohs Hardness.” https://www.britannica.com/science/Mohs-hardness, accessed 2 October 2019.

[22] Wikipedia. “Aerogel.” https://en.wikipedia.org/wiki/Aerogel, accessed 2 June 2020.

[23] Gronstal, A. “Seven Samples from the Solar System’s Birth.” Phys. Org., 28 April 2014, https://phys.org/news/2014-04-samples-solar-birth.html, accessed 2 June 2020.

[24] Horz, F., et al. “Capture of Hypervelocity Particles with Low-Density Aerogel.” NASA TM-98-201792, April 1998.

[25] National Technical Services – Chesapeake Testing. Engineering Team Manager. Personal communication, 2 October 2019.

Want to find out more about this topic?

Request a FREE Technical Inquiry!