an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

Recent Developments in Soldier and Vehicle Signature Management Technologies

Posted on May 27, 2020 | Completed on February 24, 2020 | By: Keith F. Prussing

What are the latest developments on signature management technologies for reducing visible, infrared (IR), and thermal signatures?

DSIAC subject matter experts performed a search of the open literature to locate new research pertaining to visible, infrared, and thermal signature management. The search focused on developments since 2018, when a previous summary was provided. Areas covered include manipulation of emissivity; reflectivity; adsorption; refraction and backscatter using multispectral camouflage materials; multilayered, cavity-coupled plasmonic systems; metamaterials; nanoparticles; carbon nanotubes; glass microspheres; nanofibers; electrochromatic fabric; metasurfaces; waveguides; and lenticular lens materials.

1.0 Introduction

Defense Systems Information Analysis Center (DSIAC) material and signature management subject matter experts (SMEs) from Georgia Tech Research Institute performed a search of the open literature to locate new research pertaining to visible, infrared (IR), and thermal signature management. The search focused on developments since 2018.

1.1 U.S. Army Ultra-Lightweight Camouflage Net System and Multispectral Camouflaging Nets

A recent development is the U.S. Army ordering a new ultra-lightweight camouflage net system (ULCANS) from Saab [1] and FibroTex [2]. The Saab Barracuda ULCANS offers multispectral, lightweight, and easy-to-handle camouflage that protects against visual and near-IR, thermal infrared, and broadband radar threats [3]. The FibroTex 2D technology ULCANS provides more persistent IR, thermal, and counter-radar performance at a greater range. The FibroTex design is two-sided to allow different patterns and capabilities on each side. This allows soldiers and stationary systems to blend in with different operating environments with a single piece of equipment.

Closely related to the ULCANS are multispectral camouflaging nets (MCNs). An example MCN is the multispectral camouflage products produced by PROFILE Equipment [4]. These materials are designed to “blend with the background” instead of simply blocking the self-emission. An India-based competitor, Sterlite Camotech (https://www.sterlitecamotech.com/), manufactures nets made of synthetic fabrics and near-IR reflective coatings to improve stealth capabilities in the visible, near-IR, thermal IR, and broadband radar wavebands.

1.2 Multilayered, Cavity-Coupled, Plasmonic, Adaptive IR Camouflage

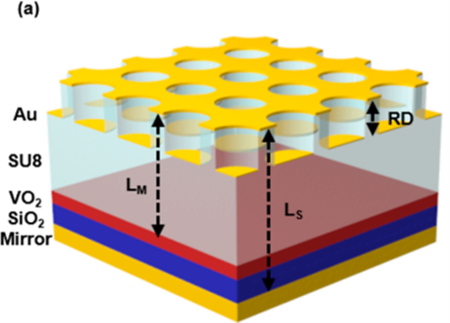

A group at the University of Central Florida reported on adaptive IR (3–5 µm and 8–12 µm) camouflage systems actuated by exploiting the semiconductor-to-metal phase transition of vanadium oxide, VO2, which modifies the reflection spectra of the multilayered, cavity-coupled plasmonic system [5]. In its semiconducting state, VO2 is transparent to infrared such that incident light couples to the entire cavity length. However, in the metallic state, VO2 behaves like a mirror and shortens the cavity length by isolating the SiO2 layer from the system. The optical response of the described system may be controlled by changing the hole/disk diameter and periodicity of the plasmonic crystal. Figure 1 depicts a schematic illustration of the plasmonic system. Increasing the VO2 temperature results in active information camouflage, as demonstrated in Figure 2, where the reflection from a device with a 1.3 × 1.7 mm2 image of Albert Einstein is actively controlled.

Figure 1: Schematic Illustration of the Plasmonic System With Tunable Cavity Length [5].

![]()

Figure 2: A Set of FTIR Scan Generated Images of the Plasmonic Surface Acquired for Semiconducting (T = 295 K), Phase-Separated (T = 320 K), and Metallic (T = 360 K) States of VO2 [5].

1.3 Hierarchical Metamaterials for Multispectral Camouflage

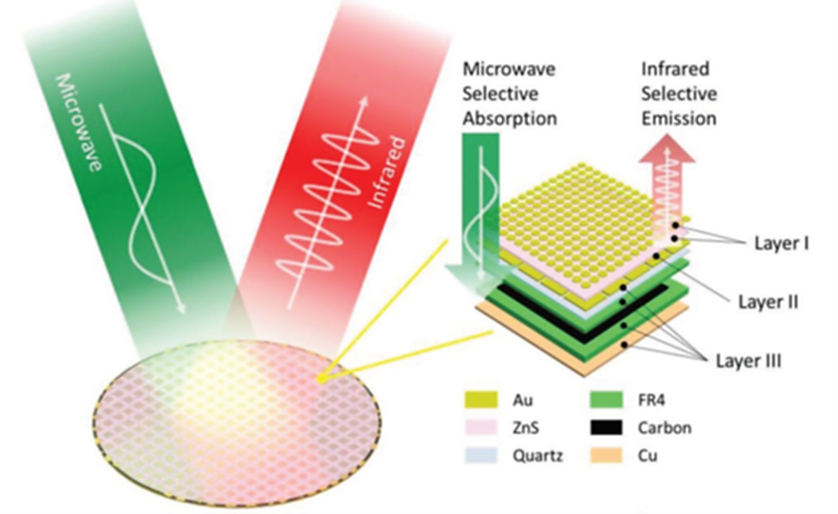

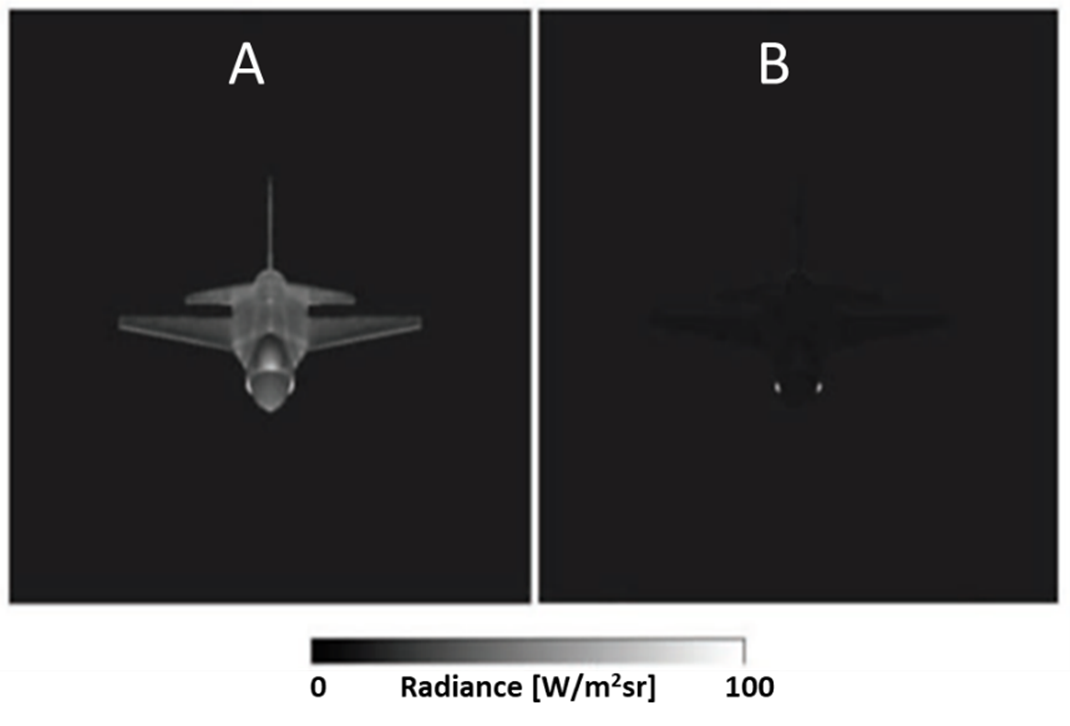

A Korean team demonstrated the application of hierarchical metamaterials (HMMs) for multispectral camouflage in the IR (8–12 µm) and microwave (2.5–3.8 cm) spectral ranges [6]. Control of IR and microwave signature from the target is accomplished through the emission of absorbed energy by microwave selective absorbers and IR-selective emitters, as schematically illustrated in Figure 3. They evaluated the effectiveness of the HMM-based stealth coating using simulations of IR and microwave signatures of supersonic aircraft. Figure 4 provides graphical results of the HMM surface, though the article shows the simulated microwave signature for a supersonic aircraft with and without the HMM surface. With the HMM stealth surface, the visibility in the IR and microwave ranges were reduced by 70% and 99%, respectively.

Figure 3: Principle of Operation and Schematic of the HMM Structure [6].

Figure 4: Simulated IR Signature for a Supersonic Aircraft Without (A) and With (B) the HMM Surface [6].

1.4 Metamaterial, Selective Emitter for IR Camouflage

Lee et al. used a metamaterial selective absorber/emitter (MSAE) structure for IR camouflage (3–5 µm and 8–12 µm) [7]. To ensure the IR camouflage of the target, the emissive energy of the target should be decreased leading to an increase in the target’s temperature due to the accumulated energy. By controlling geometrical parameters of the MSAE structure, in particular, diameter and pitch of metal discs, energy balance between emitting and accumulated energies of the target is tweaked to realize effective IR camouflage.

1.5 Thermal Color and Emissivity of Pigments on Camouflage Clothing

Pimenta et al. investigated thermal color and emissivity of white, black, yellow, magenta, and cyan-blue pigments printed on cotton and polyester knitted fabrics for the development of diurnal and nocturnal camouflage clothing [8]. Emissivity of printed fabric samples was evaluated by using a thermal manikin and an adiabatic chamber. All printed pigments showed yellow thermal color, the predominant thermal color in diurnal and nocturnal thermal images of outdoor environments at 24 ˚C and 18 ˚C, respectively.

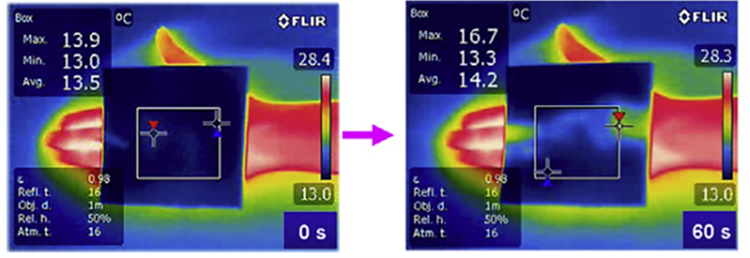

1.6 Multifunctional Thermal Camouflage Using Nanoparticles on Leather

Wang et al. developed a multifunctional thermal camouflage armor by direct editing the natural insulation structure of cowhide [9]. A layer of SiO2 nanoparticles was grown on the front and back sides of the hierarchically-fibrous scaffold of leather. As shown in Figure 5, the thermal signature of a human hand is effectively shielded using the leather-based armor. The inherent disadvantage of leather-based armor is hydrophilicity caused by the microporous structure of the cowhide. However, adding a polydimethylsiloxane coating on the front side of the SiO2-leather/SiO2 material increases water contact angle to 130˚, which still presents thermal camouflage performance even when water was poured onto its surface. Finally, it was shown that leather-based armor is also flame resistant and cannot be ignited, even in direct contact with the flame.

Figure 5: Thermal Image of Human Hand Covered by the Leather-Based Armor [9].

1.7 Carbon Nanotube-Doped Aerogel for Thermal Camouflage

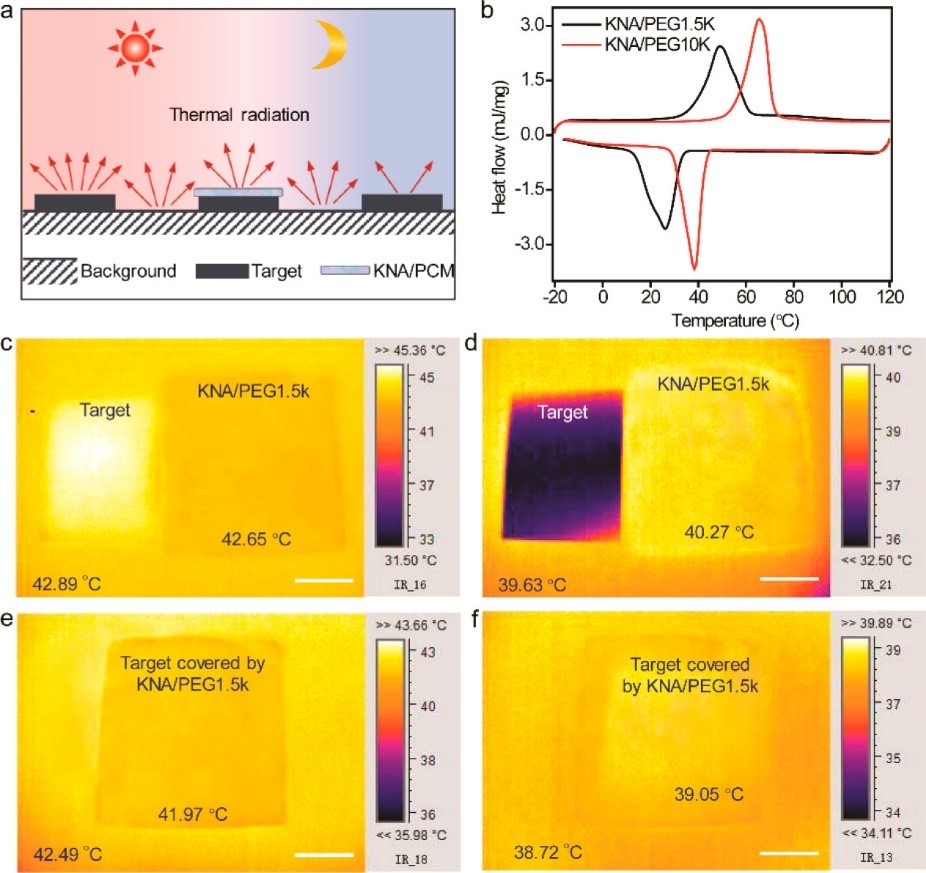

Xu et al. designed a fabric composite comprised of a carbon nanotube-doped aerogel (CNTA) sandwich structure deposited on one side of polyimide (PI) fabric by hot pressing and then coated with a low-emissivity, Al-doped ZnO (ZAO) on the other side [10]. The low surface emissivity and thermal conductivity demonstrated by the composite makes it a good candidate for the thermal camouflage applications. Thermal images of PI fabric and PI-fabric-based composite at different stages of development (with ZAO coating only, with CNTAs only, and final sandwich ZAO/CNTAs/PI fabric structure) are shown in Figure 6.

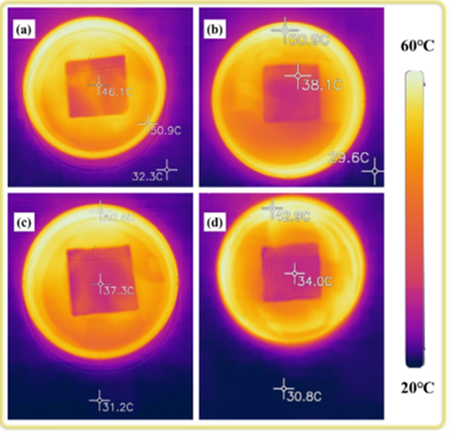

Figure 6: IR Thermal Images of (a) PI Fabric, (b) ZAO/PI Fabric, (c) CNTAs/PI Fabric, and (d) ZAO/CNTAs/PI Fabric [10].

1.8 IR Camouflage Fabric Based on Silver-Plated, Hollow Glass Microspheres

Xu et al. also reported on effective IR camouflage fabric based on silver-plated, hollow glass microspheres doped with aluminum powder [11]. They were produced by PANi in situ polymerized first and followed with electroless plating.

Recently, scientists from the Chinese Academy of Sciences’ Suzhou Institute of Nanotech and Nanobionics demonstrated IR stealth properties with materials made of Kevlar nanofibers drenched in polyethylene glycol (PEG) [12, 13]. The combination of thermal insulation from the Kevlar nanofibers and IR emission absorption from the PEG makes the material suitable for IR concealing technologies. Figure 7 depicts the effectiveness of the Kevlar-PEG material for IR masking of a ceramic plate under sunlight and darkness conditions.

Figure 7: Infrared stealth property of KNA/PEG under outdoor environment. (a) Schematic representation of the infrared stealth mechanism of KNA/PEG under outdoor environment. (b) DSC curves of KNA/PEG1.5k and KNA/PEG10k. (c–f) Thermal images displayed on the infrared thermal camera for exposure to sunlight (c,e) and turning off the sunlight (d,f). The sunlight was controlled by a solar simulator [13].

1.9 Electrochromatic Color-Changing Fabric

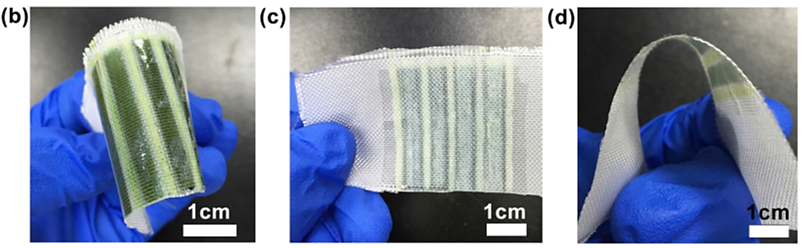

Yu et al. developed a novel, wearable electrochromic fabric that changes color between vegetable green and soil brown [14]. In addition, the fabric is flexible, stable, and lightweight, which makes it suitable for fabricating flexible transparent devices on plastics and “chameleon camouflage” on human skin. Preparing the fabric involved spray coating commercially available indium tin oxide liquid onto synthetic fabric through the striped mask. The bent, back, and side views of the developed fabric are shown in Figure 8.

Figure 8: Bent State (Left), Back View (Middle), and Side View (Right) of the Developed Fabric [14].

1.10 Manipulating Material Refractive Index and Mie Scattering for Cloaking

Additionally, researchers from the Tokyo Institute of Technology (Tokyo Tech) described a way of making a submicron-sized cylinder disappear without using specialized coatings [15]. Mie scattering theory was used to visualize the relationship between the cylinder’s light-scattering efficiency and refractive index. Next, they determined that invisibility would occur when the refractive index of the cylinder ranges from 2.7 to 3.8. Some useful materials within this range are silicon (Si), aluminum arsenide (AlAs), and germanium arsenide (GaAs). Scientists confirmed the conditions for achieving invisibility with numerical modeling based on the finite‑difference time-domain method. University of Extremadura researchers proposed invisibility cloaking based on filler cloaking, which makes the object and the filler jointly invisible [16, 17].

1.11 Curvilinear Metasurface for Electromagnetic Cloaking

In addition to pure materials, scientists from Edinburgh Napier University, in collaboration with Queen Mary University of London and Qineteq Group Ltd., have developed a curvilinear metasurface that could be used to hide a three-dimensional (3-D) object [18, 19]. In an Edinburgh Napier University blog post, there is a 3-D rendering of the MetaSurface surface material making a 3-D object underneath invisible to electromagnetic waves. This surface will make it possible to obtain sensors that can adapt themselves to conform to any curvilinear body [18].

1.12 Stretchy Polymer With Aluminum Dots to Control IR Reflectivity

A team of researchers from the University of California, Irvine, created a device inspired by a squid’s skin [20]. They deposited dots of aluminum on a stretchy polymer. When researchers expanded a dot, it reflected more IR light than in the contracted state. They demonstrated a working prototype of the reflector. When expanded, the device reflected more heat than its surroundings, making it visible to an IR camera. In its resting state, the reflector blended into the thermal background and became invisible in the IR spectral range.

1.13 Waveguide Structure Cloaks Objects in Water to Reduce Drag

Two types of invisibility cloaks for water applications were designed by researchers from China and South Korea [21]. The Chinese team installed long, thin iron platforms on the bottom of a water‑filled tank, with a cylinder at the center [22]. This configuration operated as a waveguide to confine waves to a desired location. The team from Korea created a cloak by enclosing an object within a ring of 523 specially-designed small pillars—the arrangement of the pillars deflected incoming fluid flow, resulting in zero drag on the hidden object [24].

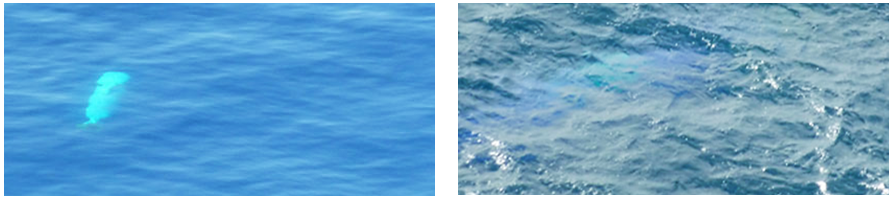

1.14 Dynamic Camouflage With IR Signature Management

Canopy Defense (https://canopydefense.com/) develops a variety of concealing solutions for military applications [24, 25]. In particular, they develop dynamic camouflage for military personnel and coatings with IR signature management for aircraft and other vehicles. Their dynamic camouflage can adjust visual shape, color, brightness, and pattern frequency while stationary or moving. This can be combined with their IR spectrum signature management solutions for added effectiveness. Their vehicle coatings provide tailored camouflage performance in the thermal spectrum (Figure 9).

Figure 9: Submarine Located 10 m Underwater – Control Paint (Left) and Stealth Coating (Right) [25].

1.15 Ceramic Coatings for Weapon System Visual and Near-Infrared (NIR) Camouflage

Cerakote (https://www.cerakote.com/), a division of NIC Industries, Inc., focuses on ceramic coatings to manage visual and near-IR signatures (but not thermal) of firearms [26, 27]. These coatings can be applied to other equipment as well. Their Gen II NiR collection of ceramics provides superior chemical and corrosion resistance, as well as increased durability, reliability, and maintainability, under a wide variety of environmental conditions. These ceramics are available in several shades to match natural environments. The coating is designed to conform to the NIR reflectivity standards outlined in U.S. military specification MIL-C-53039D [28] and MIL-DTL-44436, as well as Australian Defense Standard DEF (AUST) 8746 [29]. Sales of the Gen II NiR coatings are restricted to military and law enforcement agencies only. In an article about reducing the visual-IR signature detection of weapons, Cerakote shows an example of the Gen II NiR nighttime performance in the 700–1400 nm NIR spectrum. Reflectivity performance varies with color. For example, HIR-146 Graphite Black is between 5% and 25%, while something like CIR-267 MagPul Flat Dark Earth would be between 50% to 55%.

1.16 Electromagnetic Fractal Metamaterials for Cloaking and Shielding

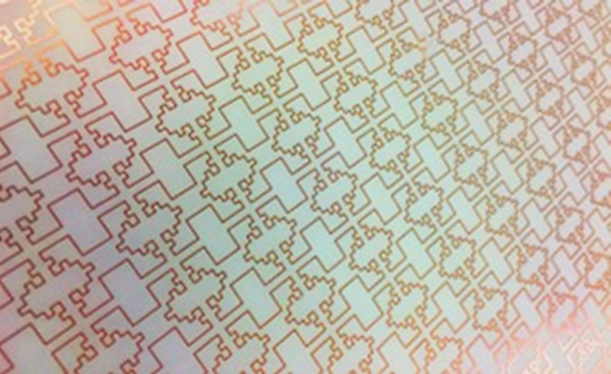

Fractal Antenna Systems, Inc. (https://www.fractenna.com/) manufactures metamaterials for cloaking and shielding applications. For cloaking applications, wideband resonators absorb electromagnetic radiation and “cloak” the object by canceling backscatter and enhancing front scatter. For shielding applications, wideband fractal metamaterials prevent electromagnetic penetration by absorbing radiation and diverting it through an evanescent surface wave effect that allows controlled routing and distribution of energy across the surface [30]. An example of an electromagnetic fractal metamaterial is shown in Figure 10.

Figure 10: Electromagnetic Fractal Metamaterial Composed of Closely-Spaced Conductive Resonators (Credit: Courtesy Fractal Antenna Systems, Inc.).

1.17 Multispectral Lensatic Polymer for NIR, Visual, and Near-UV Cloaking

HyperStealth Biotechnology Corp. (http://hyperstealth.com/) manufactures Quantum Stealth, a multispectral polymer cloaking material. DSIAC’s previous TI on cloaking technologies reported early versions of the material composed of a single lenticular lens sheet of material. This material could be relatively thin and flexible, allowing it to be wrapped around objects. It functions by refracting broadband light around the object so that it seems to disappear (see Figure 11). The effect depends on the viewing aspect angle and target distance behind the material. In these early versions, the cloaking effect is best with 15 inches or greater separation for personnel-sized objects and 12 feet or better for main battle tank-sized objects [31]. The material can maintain the cloaking effect over a fairly broad approach angle; however, when viewed from certain aspect/approach angles, especially when a light interference phase shift occurs, the target will be visible and somewhat magnified. If the target is too wide with respect to the material or too close to the material, it will become partially visible.

Figure 11: Quantum Stealth Material Partially Obscures Man (Left) and White Helmet on Black Background and Black Helmet on White Background (Right) [31].

The material works to some degree in the NIR, visual, and near-ultraviolet spectral ranges, as shown in Figure 12.

Figure 12: Quantum Stealth Material Demonstrated Obscuring Person in Various Spectral Bands [31].

The company has recently filed multiple patents and released new videos of the technology in use. The latest version 13 of the material is composed of ~100 lenses per square inch (HyperStealth claims to be working on getting this up to 200 lenses per square inch). Material thickness is about ¼ inch and weighs ~1 lb per square foot. Required standoff distance has been reduced to ~2 inches for a person-sized object and 2 feet for a main battle tank-sized object. The material is generally targeted for use on ground vehicles and structures, but HyperStealth does have a goal of developing a lightweight parachute-like material that can cover military personnel uniforms, face/head, etc., and still allow them to breath, see, and hear [32].

References

[1] Army Technology. “Saab to Deliver Ultra-Lightweight Camouflage Net Systems to U.S. Army.” https://www.army-technology.com/news/saab-camouflage-net-us, 22 November 2018.

[2] FibroTex. “After Two Years of Testing, the U.S. Army has Selected FibroTex USA for its Next-Gen Ultra-light Camouflage Netting System Against Electromagnetic Threats.” http://www. fibrotex-tech.com/fibrotex-wins-us-army’s-480-million-next-gen-camo-netting-contract, accessed January 2020.

[3] Saab. “Advanced Camouflage Protection.” https://saab.com/land/signature-management/force-integrated-systems/mcs_mobile_camouflage_system/, accessed January 2020.

[4] PROFILE Equipment. “Multi-Spectral Camouflage.” https://www.profile-equipment.com/ products-2/multi-spectral-camouflage/, accessed January 2020.

[5] Chandra, S., D. Franklin, J. Cozart, A. Safaei, and D. Chanda. “Adaptive Multispectral Infrared Camouflage.” ACS Photonics, vol. 5, no. 11, pp. 4513─4519, http://www.nanoscience.ucf.edu/chanda/files/ACS_Photonics_Adaptive%20Multispectral%20Infrared%20Camouflage.pdf, 12 September 2018.

[6] Kim, T., J.-Y. Bae, N. Lee, and H. H. Cho. “Hierarchal Metamaterials for Multispectral Camouflage of Infrared and Microwaves.” Advanced Functional Materials, vol. 29, no. 10, https://onlinelibrary.wiley.com/doi/full/10.1002/adfm.201807319, 7 March 2019.

[7] Lee, N., T. Kim, J.-S. Lim, I. Chang, and H. H. Cho. “Metamaterial-Selective Emitter for Maximizing Infrared Camouflage Performance With Energy Dissipation.” ACS Applied Materials & Interfaces, vol. 12, no. 23, pp. 21250─21257, https://pubs.acs.org/doi/10.1021/acsami. 9b04478, 16 May 2019.

[8] Pimenta, C., C. Morais, and R. Fangueiro. “The Thermal Colour and the Emissivity of Printed Pigments on Knitted Fabrics for Application in Diurnal Thermal Camouflage Garments.” Key Engineering Materials, vol. 812, pp. 127─133, https://www.scientific.net/KEM.812.127, July 2019.

[9] Wang, X., Y. Tang, Y. Wang, L. Ke, X. Ye, X. Huang, and B. Shi. “Leather Enabled Multifunctional Thermal Camouflage Armor.” Chemical Engineering Science, vol. 196, pp. 64─71, https://www.sciencedirect.com/science/article/pii/S0009250918308467, 16 March 2019.

[10] Xu, R., W. Wang, and D. Yu. “A Novel Multilayer Sandwich Fabric-Based Composite Material for Infrared Stealth and Super Thermal Insulation Protection.” Composite Structures, vol. 212, pp. 58─65, https://www.sciencedirect.com/science/article/pii/S0263822318339977, 15 March 2019.

[11] Xu, R., W. Wang, and D. Yu. “Preparation of Silver-Plated Hollow Glass Microspheres and Its Application in Infrared Stealth Coating Fabrics.” Progress in Organic Coatings, vol. 131, pp. 1─10, https://www.sciencedirect.com/science/article/pii/S0300944018307240?via%3Dihub, June 2019.

[12] Patel, P. “Packable Kevlar Cloak Provides Infrared Stealth Across Changing Temperatures.” Chemical & Engineering News, https://cen.acs.org/materials/coatings/Packable-Kevlar-cloak-provides-infrared/97/web/2019/02, 27 February 2019.

[13] Lyu, J., Z. Liu, X. Wu, G. Li, D. Fang, and X. Zhang. “Nanofibrous Kevlar Aerogel Films and Their Phase-Change Composites for Highly Efficient Infrared Stealth.” ACS Nano, vol. 13, no. 2, pp. 2236-2245, https://pubs.acs.org/doi/10.1021/acsnano.8b08913, 30 January 2019.

[14] Yu, H., M. Qi, J. Want, Y. Yin, Y. He, H. Mong, and W. Huang. “A Feasible Strategy for the Fabrication of Camouflage Electrochromic Fabric and Unconventional Devices.” Electrochemistry Communications, vol. 102, pp. 31─36, https://www.sciencedirect.com/science/article/pii/S1388248119300645, May 2019.

[15] Tokyo Institute of Technology. “Study Opens a New Route to Achieving Invisibility Without Using Metamaterials.” Phys Org., https://phys.org/news/2019-04-route-invisibility-metamaterials.html, 23 April 2019.

[16] University of Extremadura. “New Technique to Make Objects Invisible Proposed.” ScienceDaily, https://www.sciencedaily.com/releases/2018/11/181126123411.htm, 26 November 2018.

[17] Serna, A. L., J. Molina, J. Rivero, L. Landesa, and J. M. Taboada. “Multilayer Homogeneous Dielectric Filler for Electromagnetic Invisibility.” Scientific Reports, no. 8, article 13923, https://www.nature.com/articles/s41598-018-32070-5, 17 September 2018.

[18] Sutherland, S. “Curvilinear MetaSurfaces for Wave Manipulation: A Closer Step to Invisibility Cloak.” Edinburgh Napier University School of Engineering and the Built Environment (SEBE) Blog, https://blogs.napier.ac.uk/sebe-research/curvilinear-metasurfaces-for-wave-manipulation-a-closer-step-to-invisibility-cloak/, 4 April 2019.

[19] Spada, L. L., C. Spooner, S. Haq, and Y. Hao. “Curvilinear MetaSurfaces for Surface Wave Manipulation.” Scientific Reports, no. 9, article 3107, https://www.nature.com/articles/

s41598-018-36451-8, 28 February 2019.

[20] Nature. “A Squid-Skin-Inspired Invisibility Cloak.” https://www.nature.com/articles/ d41586-018-04009-3, 30 March 2018.

[21] Yirka, B. “Two Teams Build Invisibility Cloaks for Water Applications.” Phys Org., https://phys.org/news/2019-08-teams-invisibility-cloaks-applications.html#:~:text=Two% 20teams%20of%20researchers%2C%20one,the%20journal%20Physical%20Review%20Letters, 14 August 2019.

[22] Zou, S., Y. Xu, R. Zatianina, C. Li, X. Liang, L. Zhu, Y. Zhang, G. Liu, Q. H. Liu, H. Chen, and Z. Wang. “Broadband Waveguide Cloak for Water Waves.” Physical Review Letters, no. 124, https://journals.aps.org/prl/abstract/10.1103/PhysRevLett.123.074501, 13 August 2019.

[23] Park. J., J. R. Youn, and Y. S. Song. “Hydrodynamic Metamaterial Cloak for Drag-Free Flow.” Physical Review Letters, no. 123, https://journals.aps.org/prl/abstract/10.1103/ PhysRevLett.123.074502 , 13 August 2019.

[24] Canopy Defense. “Dynamic Camouflage.” https://canopydefense.com/dynamic-camouflage/, accessed 4 February 2020.

[25] Canopy Defense. “Signature Management Coatings.” https://canopydefense.com/

signature-heat-management/, accessed 4 February 2020.

[26] Cerakote. “Cerakote Gen II Coatings: Reduced Weapons Visual-IR Signature Detection.” https://www.cerakote.com/news/62/cerakote-gen-ii-coatings-reduced-weapons-visual-ir-signature-detection, accessed 4 February 2020.

[27] Griffin, R. “Cerakote Gen II Coatings: Reduced Weapons Visual-IR Signature Detection.” Cerakote, https://www.cerakote.com/news/article/cerakote-gen-ii-coatings-reduced-weapons-visual-ir-signature-detection/, accessed 4 February 2020.

[28] U.S. Department of Defense. Coating, Aliphatic Polyurethane, Single Component, Chemical Agent Resistant. MIL-C-53039D, 24 January 2011.

[29] Australian Department of Defence. Print Design, Disruptive Pattern Standard. Australian Defense Standard DEF (AUST) 8746, 31 January 2012.

[30] Fractal Antenna Systems, Inc. “Our Technology.” https://www.fractenna.com/our/our.html, accessed 4 February 2020.

[31] HyperStealth Biotechnology Corp. “Invisibility Invented.” http://hyperstealth.com/, accessed 4 February 2020.

[32] Crane, D. “Hyperstealth Quantum Stealth: Light-Bending, Multi‑spectral ‘Invisibility Cloaking’.” Adaptive Camo (Camouflage) Goes Very Public, and Mainstream! Defense Review, https://www.defensereview.com/hyperstealth-quantum-stealth-light-bending-multi-spectral-invisibility-cloaking-adaptive-camo-camouflage-goes-very-public-and-mainstream-videos/, 23 October 2019.

Want to find out more about this topic?

Request a FREE Technical Inquiry!