an email newsletter released every month highlighting the latest articles, events, technical inquires, and voices from the community

Using Shape Memory Alloys as an Intermediate for Materials With Dissimilar Coefficients of Thermal Expansion

Posted on June 10, 2020 | Completed on June 4, 2020 | By: Richard Piner, Doyle T. Motes III

Can the high-strain recovery and temperature memory aspects of shape memory alloys make them useful for developing a coupling between the dissimilar materials of high-temperature materials?

The Defense Systems Information Analysis Center received a technical inquiry on the topic of joining dissimilar materials. Historically, the integration of high-temperature materials used for leading edges, control surfaces, heat shields, etc. with metallic structural components has been challenging due to the brittle nature of the high-temperature materials and the difference in coefficients of thermal expansion from the more structural components. Information was requested about using the high strain recovery and temperature memory aspects of shape memory alloys (SMAs) to develop a coupling between these dissimilar materials. This coupling using SMAs might allow for controlled displacements and/or mitigated thermally induced stress at the integration points. The SMAs have potential as connection mechanisms between hot sections of a hypersonic vehicle and the cooler interior substructure. Materials engineering subject matter experts listed the efforts to produce these material systems (mostly sponsored by NASA) and identified several options in varying degrees of development and technology readiness levels.

1.0 Introduction

The Defense Systems Information Analysis Center (DSIAC) received support from subject matter experts (SMEs) in materials science and engineering from Texas Research Institute Austin (TRI Austin) and the University of North Texas. The SMEs used internal knowledge and performed a literature search using a combination of open sources, the Defense Technical Information Center, and university library resources to respond to the technical inquiry.

2.0 Failure Mechanisms for SMAs Required for Coupling Dissimilar Materials

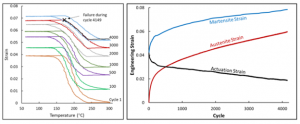

The primary anticipated failure mechanisms that might be exhibited are residual stresses and fatigue stresses associated with heating events generating irrecoverable strain (depending on the requirements of the craft. See an example in Figure 1.).

Figure 1: Irrecoverable Strain as a Result of Cycling – Increasing the Number of Cycles Causes a Decrease in the Amount of Irrecoverable Strain (Visualized as the Distance of the Strain vs. Temperature Hysteresis Curve, Left) and Evolution of the Strain in the Material as a Function of Exposed Actuation Cycles (Right) (Source: Ley et al. [1]).

The National Aeronautics and Space Administration (NASA) has researched the use of SMAs as actuators of various sorts for high-speed aircraft. Examples are shown on NASA’s website [2, 3]. In addition, a DSIAC webinar recently (29 April 2020) covered a wide range of SMA actuation topics [4].

In 2010, Akselsen published work on the joining of shape memory alloys [5]. In this research, ductile metal interlayers were required for joining nickel titanium (NiTi) alloys, and with an optimum bonding procedure, the shape recovery reached a total of 91% of the base metal. The author notes that welding SMAs is possible but produces brittle joints due to the formation of intermetallic compounds in the microstructure. The author also mentions the possibility of using additives to prevent or mitigate the formation of intermetallics but explains that very little related information is available. Brazing was studied, but again, the formation of intermetallics was a problem. A proper ductile interlayer is suggested to prevent excessive diffusion and to accommodate thermal strains associated with the mismatch in coefficients of thermal expansion (CTEs), which is precisely the problem that is sought to be avoided.

A patent from Shaw and Grummon in 2013 discusses the use of pure niobium as a transient liquid reactive braze material to fabricate cellular/honeycomb structures using Nitinol by flowing into capillary spaces between elements to be joined, creating a strong joint [6]. The authors do not mention niobium’s ability to resist strong CTE mismatches.

Oliveira et al. (2017) discuss dissimilar laser welding of superelastic NiTi and copper aluminum manganese (CuAlMn) SMAs and state specifically that if the materials joined have significantly different CTEs, the joint may fail during solidification due to residual stresses [7]. The authors did note that the superelastic properties of the joint were preserved, although an irrecoverable strain of ~2% was observed due to the unfavorable microstructure (columnar to equiaxed dendritic grain growth in the majority of the joint) in the fusion zone.

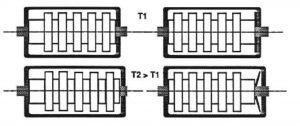

Older work from 1989 by D. Stoeckel of the Raychem Corporation, which went defunct in 1999, discusses the use of SMA springs in a governor valve as a means of temperature compensation, which may provide a path forward for the inquirer, depending on the specific means that the joining of the different structural pieces are connected to the metallic substructure [8]. In addition, the work also describes SMA washers that can be used when high forces and small motions are required (specifically, such as to compensate for different thermal expansions of dissimilar materials). The author also discusses gearboxes with steel shafts and aluminum cases in which rattling noise is caused by a decrease in the preload of the assembly with increasing temperature. Ni-Ti Belleville-type or wave washers can generate greater than 1 kN with a deflection of ~0.5 mm and restore the preload to the gearbox upon reaching its operating temperature (Figure 2). The author notes that this configuration is used by Toyota of Japan in their Sprinter/Carib cars.

Figure 2: Schematic Showing Compensation for Thermal Expansion of Dissimilar Metals in a Gearbox for Toyota’s Sprinter/Carib Cars (Source: Stoeckel [8]).

There appear to be options to potentially engineer SMAs to act as connection pieces between hot components of a hypersonic vehicle and the cool substructure. However, the temperature that the SMAs will reach is still unknown. For an SMA to be an effective, flexible joint between the different parts of the structure, it must have an appropriate temperature range and retain its desirable properties within that range, otherwise, its effect will be nullified. Transformation ranges for a number of different alloy types are shown in Table 1. Note that Table 1 is not a complete list of SMAs and their properties.

Table 1: Transformation Temperature Ranges for SMAs (Source: Swardz [9])

|

Alloy |

Composition Atomic (at.) or Weight (wt.) % |

Transformation Temperature Range (°C) |

| Ag – Cd | 44−49 at.% | -190 to -50 |

|

Au – Cd |

46.5−50 at.% | 30 to 100 |

|

Cu – Al – Ni |

14−14.5 wt.% / 3−4.5 wt.% |

-140 to 100 |

|

Cu – Sn |

approx. 15 at. % |

-120 to 30 |

|

Cu – Zn |

38.5−41.5 wt. % |

-180 to -10 |

|

Cu – Zn – (Si,Sn,Al) |

a few wt.% of (Si, Sn, Al) |

-180 to 200 |

|

In – Ti |

18−23 at. % |

60 to 100 |

| Ni – Al | 36−38 at. % |

-180 to 100 |

|

Ni – Ti |

49−51 at. % |

-50 to 110 |

|

Fe – Pt |

~ 25 at. % Pt |

approx. -130 |

|

Mn – Cu |

5−35 at. % Cu |

-250 to 180 |

Ag=silver; Al=aluminum; Au=gold; Cu=copper; Fe=iron; Mn=manganese; Ni=nickel; Pt=platinum; Si=silicon; Sn=tin; Ti=titanium; Zn=zinc

References

[1] Ley, N. A., C. Lee, R. W. Wheeler, D. C. Lagoudas, and M. L. Young. “Synchrotron Radiation X-ray Diffraction Measurements on Non-metallic Inclusions and their Effect on Fatigue Life in NiTiHf High Temperature Shape Memory Alloys.” Materials Science & Technology Conference, Portland, OR, 29 September−3 October 2019.

[2] NASA. “Shape Memory Alloy with Adjustable, Wide-Ranging Actuation Temperatures.” NP-2018-06-2577 HQ, https://ntts-prod.s3.amazonaws.com/t2p/prod/t2media/tops/pdf/LEW-TOPS-130.pdf, accessed 1 June 2020.

[3] NASA. “Spanwise Adaptive Wing.” NP-2017-07-2427-HQ, https://ntts-prod.s3.amazonaws.com/t2p/prod/t2media/tops/pdf/LEW-TOPS-124.pdf, accessed 1 June 2020.

[4] Young, M. L. “Shape Memory Alloys for DoD Applications.” Webinar, Defense Systems Information Analysis Center (DSIAC), https://www.dsiac.org/resources/webinars/shape-memory-alloys-for-dod-applications/, 29 April 2020.

[5] Akselsen, O. M. “Joining of Shape Memory Alloys,” in Shape Memory Alloys. C. Cismasiu (Ed.), ISBN: 978-953-307-106-0, InTech, https://www.intechopen.com/books/shape-memory-alloys/joiningof-shape-memory-alloys, 2010.

[6] Shaw, J. A., and D. S. Grummon. “Manufacture of Shape Memory Alloy Cellular Materials and Structures by Transient-Liquid Reactive Joining.” US8465847B2, https://patents.google.com/patent/US8465847, 18 June 2013.

[7] Oliveira, J. P., Z. Zeng, C. Andrei, F. M. Braz Fernandes, R. M. Miranda, A. J. Ramirez, T. Omori, and N. Zhou. “Dissimilar Laser Welding of Superelastic NiTi and CuAlMn Shape Memory Alloys.” Materials & Design, vol. 128, pp. 166−175, https://www.sciencedirect.com/science/article/abs/pii/S0264127517304768, 15 August 2017.

[8] Stoeckel, D. “Thermal Actuation with Shape Memory Alloys.” Raychem Corporation, https://nitinol.com/wp-content/uploads/references/076.pdf, 1989.

[9] Swardz, S. “The Way Shape Memory Alloys Work, and How Are the SMA’s ‘Trained’.” University of Washington, https://depts.washington.edu/matseed/mse_resources/Webpage/Memory%20metals/how_shape_memory_alloys_work.htm, accessed 1 June 2020.

Want to find out more about this topic?

Request a FREE Technical Inquiry!